VR37000001205JR500 Vishay, VR37000001205JR500 Datasheet

VR37000001205JR500

Specifications of VR37000001205JR500

Related parts for VR37000001205JR500

VR37000001205JR500 Summary of contents

Page 1

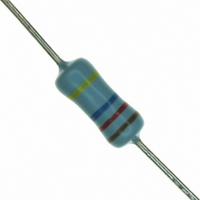

... VR37 Vishay BCcomponents Metal Glaze Leaded Resistors A metal glazed film is deposited on a high grade ceramic body. After a helical groove has been cut in the resistive layer, tinned electrolytic copper wires are welded to the end-caps. The resistors are coated with a light blue lacquer ...

Page 2

... MASS resistor using four or five colored bands in accordance with (mg) IEC 60062, marking codes for resistors and capacitors. Yellow and grey are used instead of gold and silver because 457 metal particles in the lacquer could affect high-voltage properties. filmresistorsleaded@vishay.com Vishay BCcomponents (1) PACKAGING TOLERANCE F = ± ...

Page 3

... VR37 Vishay BCcomponents OUTLINES The length of the body ( measured by inserting the 1 leads into holes of two identical gauge plates and moving FUNCTIONAL PERFORMANCE PRODUCT CHARACTERIZATION Standard values of nominal resistance are taken from the E96/E24/E12 series for resistors with a tolerance of ± LIMITING VALUES ...

Page 4

... Thermal shock 260 ° from body 30 min °C and 30 min at + 155 °C; 5 cycles filmresistorsleaded@vishay.com Vishay BCcomponents 0.4 0.8 Temperature rise (ΔT) at the lead end (soldering ...

Page 5

... VR37 Vishay BCcomponents TEST PROCEDURES AND REQUIREMENTS IEC IEC 60068-2- 60115-1 TEST TEST CLAUSE METHOD 4.20 29 (Eb) Bump 4.22 6 (Fc) Vibration 4.23 Climatic sequence: 4.23.2 2 (Ba) Dry heat Damp heat (accelerated) 4.23.3 30 (Db 4.23.4 1 (Aa) 4.23.5 13 (M) Low air pressure Damp heat (accelerated) 4 ...

Page 6

... Vishay product could result in personal injury or death. Customers using or selling Vishay products not expressly indicated for use in such applications their own risk and agree to fully indemnify and hold Vishay and its distributors harmless from and against any and all claims, liabilities, expenses and damages arising or resulting in connection with such use or sale, including attorneys fees, even if such claim alleges that Vishay or its distributor was negligent regarding the design or manufacture of the part ...