LM3 BANNER ENGINEERING, LM3 Datasheet - Page 13

LM3

Manufacturer Part Number

LM3

Description

Photoelectric Sensor

Manufacturer

BANNER ENGINEERING

Datasheet

1.LM1.pdf

(32 pages)

Specifications of LM3

Timing Function

On-Delay And Off-Delay

Time Range

None To Output Follows Input

Application

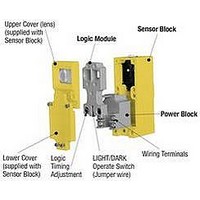

Interconnecting the power block and scanner block

Brand/series

Multi-Beam®

Function

Module, Logic

Includes

Blade & socket connector

Logic Type

ON⁄OFF, Light or Dark Operate

Sensing Mode

Adjustable Field

Technology

Photoelectric

Accessory Type

Logic Module

Lead Free Status / Rohs Status

RoHS Exempt Product

For Use With

Multi-Beam Sensors

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

LM30-00J051203E

Manufacturer:

MONRSUN

Quantity:

20 000

Part Number:

LM3000ASQ/NOPB

Manufacturer:

NS/国半

Quantity:

20 000

Company:

Part Number:

LM3000SQ/NOPB

Manufacturer:

National Semiconductor

Quantity:

1 820

Company:

Part Number:

LM300Q5

Manufacturer:

SAMSUNG

Quantity:

1 000

Company:

Part Number:

LM300W01-A1

Manufacturer:

SAMSUNG

Quantity:

1 000

Company:

Part Number:

LM300W01-STA1

Manufacturer:

SAMSUNG

Quantity:

1 000

Company:

Part Number:

LM300W01-STA4 L

Manufacturer:

SAMSUNG

Quantity:

1 000

Scanner block model SBFV1 supplies visible red light to the emitter half of a glass fiber optic photoelectric system. Visible light sensors have less optical energy

as compared to infrared systems. There are, however, some sensing situations which require visible light wavelengths in order to realize adequate optical contrast.

Opposed fibers using visible red light are used to reliably sense translucent materials (e.g. plastic bottles) which appear transparent to infrared opposed sensors. Fiber

assembly model BT13S used with a the model L9 or L16F lens makes an excellent visible light sensing system for retroreflective code reading as well as many short-

range retroreflective applications (e.g. retro scanning across a narrow conveyor). When combined with a bifurcated fiber, model SBFV1 may be used for color

registration sensing for applications where there is a large difference between the two colors (e.g. black-on-white). For combinations of red-on-white, however,

the visible-green light source of model SBFVG1 (below) is needed. Visible light emitters are also helpful for visual system alignment and maintenance.

MULTI-BEAM

VISIBLE GREEN LIGHT SOURCE

VISIBLE RED LIGHT SOURCE

FIBER OPTIC Mode

(glass fiber optics)

OPPOSED MODE

RETROREFLECTIVE MODE

DIFFUSE MODE

(REGISTRATION CONTROL)

FIBER OPTIC Mode

(glass fiber optics)

for COLOR SENSING

Sensing Mode

OBJECT

OBJECT

RETRO TARGET

OBJECT

SBFV1

Range: see excess gain

curves

Response: 1ms on/off

Repeatability: 0.3ms

Beam: visible red, 650nm

Fiber optic information:

IT13S: individual assembly

.06in (1,5mm) dia. bundle

IT23S: individual assembly

.12 in. (3mm) dia. bundle

BT13S: bifurcated assem-

bly, .06 in. (1,5mm) dia.

bundle

BT23S: bifurcated assem-

bly, .12 in. (3mm) dia.

bundle

L9: .5in. (12mm) dia. lens

L16F: 1.0 in. (25mm) dia.

lens

For information on the

complete line of glass fiber

optics, see Banner product

catalog.

Convergent beam sensors like model SBCVG1 are often used for color registration sensing. However, there are

some registration applications where the use of bifurcated fiber optics is beneficial. Fiber optics are able to fit

into tight locations which are too small for a convergent sensor. Fibers also allow a choice of image size. It is

important to create an image size which is smaller than the registration mark in order to maximize optical contrast

and to ease sensor response requirements. Fibers allow a match of the light image to the geometry of the

registration mark. Scanner block model SBFVG1 will sense most bold color differences, including red-on-white.

Use only power blocks which switch dc (e.g. PBT, PBP, PBO, PBAT, etc.) for fast response.

SBFVG1

Range:

Response: 1 ms on/off

Repeatability: 0.3ms

Beam: visible green,

560nm

3- & 4-wire Scanner Blocks

Models

see excess gain curve

E

X

C

E

S

S

G

A

I

N

E

X

C

E

S

S

G

A

I

N

E

X

C

E

S

S

G

A

I

N

E

X

C

E

S

S

G

A

I

N

I

I

I

I

1000

1000

1000

1000

100

100

100

100

10

10

10

10

.01 IN

..1 IN

..1 FT

.01 IN

1

1

1

1

Excess Gain

with IT23S

fibers

Retroreflective mode,

with BRT-3 reflector

BT13S fibers

Diffuse mode

Diffuse mode

with L9 lens,

BT13S fiber

with IT13S

fibers

1 IN

1 FT

.1 IN

.1 IN

DISTANCE

DISTANCE

DISTANCE

DISTANCE

(Range based on

90% reflectance

white test card)

(Range based on

90% reflectance

white test card)

BT23S fibers

Opposed mode

BT23S

fiber

SBFVG1

SBFV1

SBFV1

10 IN

10 FT

SBFV1

1 IN

1 IN

with L16F lens,

BT13S fiber

with IT23S

fibers, L9

lenses

100 IN

100 FT

10 IN

10 IN

I

N

C

H

E

S

I

N

C

H

E

S

I

N

C

H

E

S

I

N

C

H

E

S

.075

.025

.025

.075

.075

.025

.025

.075

1.0

1.5

1.5

DISTANCE TO 90% WHITE TEST CARD--INCHES

DISTANCE TO 90% WHITE TEST CARD--INCHES

1.0

.05

.05

.05

.05

Beam Pattern

.5

0

0

.5

0

0

2

4

6

6

2

4

0

0

0

0

SBFV1

SBFVG1

SBFV1 opposed mode

SBFV1 retroreflective mode

with

L9 lenses

IT13S fibers

OPPOSED DISTANCE--INCHES

DISTANCE TO REFLECTOR--FEET

BT13S fibers

.3

.1

3

4

BT23S fiber

diffuse mode

.6

.2

6

8

with

L16F lenses

with BRT-3 reflector

IT23S fibers

9

12

.9

.3

BT13S fibers

BT23S fibers

12

16

1.2

.4

15

20

1.5

.5

13