XCMD2110M12 SQUARE D, XCMD2110M12 Datasheet - Page 214

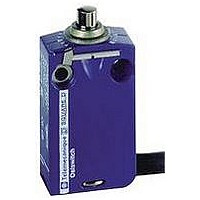

XCMD2110M12

Manufacturer Part Number

XCMD2110M12

Description

LIMIT SWITCH, 1NO.1NC, 240VAC, 250VDC, 3A

Manufacturer

SQUARE D

Datasheet

1.XCKD2102N12.pdf

(246 pages)

Specifications of XCMD2110M12

Actuator Style

Top Plunger

Operating Force Max

0.06N

Switch Operation

(ON)

Contact Voltage Ac Max

240V

Contact Voltage Dc Max

250V

Contact Current Ac Max

3A

Contact Current Dc Max

3A

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

- Current page: 214 of 246

- Download datasheet (20Mb)

Limit Switches

9007T and FT Severe Duty Mill and Foundry Switches

Conforming to NEMA A600 and UL508

Interpretation of Catalog Numbers:

page 239

214

Description

9007T Mill Switches

Use the 9007T Mill switches instead of other limit switches in

the following applications:

•

•

•

9007FT Foundry Switches

The 9007FT Foundry switches are for use in foundries or mills

where the applications described above are required, and

where falling foundry sand or similar material could build up

and jam the operating mechanism. The shaft has a dust boot

and extends from the switch case, preventing sand build up

around the shaft. The devices can withstand hot falling sand

up to 300° F (149° C.).

© 1997–2007 Schneider Electric All Rights Reserved

Where the current load exceeds the typical heavy duty limit

switch contact rating of 10 A and falls within the range of

up to 20 A continuous.

Where an operating sequence is required that is not

possible on other limit switches. Fifteen sequences are

available. Universal type has twelve different operating

sequences with CW only, CCW only and neutral position.

Standard type has three operating sequences with CW and

CCW operation.

Where higher reset forces are required due to foreign

material interfering with lever arm operation, or where long

heavy arms must reset against gravity.

Application Information

Type T — Ideal for applications requiring extra heavy duty contact ratings, or higher operating and reset

forces. Rugged mechanical construction with several different operating sequences in one basic switch.

Type FT — Designed specifically for rough foundry application. The shaft is entirely beyond the switch

case to prevent jamming of the lever arm due to build up of sand. A dust boot is furnished as standard to

further prevent sand packing and allow free movement of the lever arm. An extra long shaft bearing

makes the switch extremely rugged and able to handle the rough applications encountered in foundries,

mills, machine tool and similar industries. The switch will withstand hot falling sand up to 300° F (149

Type T and FT

Enclosure — Oil-tight, dust-tight, water-tight, drip-tight meets NEMA Types 2, 4, and 13 requirements.

Die cast zinc construction.

Operating Sequences — Fifteen sequences available. Universal type has 12 different operating

sequences with CW only, CCW only, and neutral position operation. Standard type has three operating

sequences with CW and CCW operation. Various sequences will give quick make and break,

spring return with maintained contact, or slow make and break. Most sequences are convertible by

removing the base plate and adjusting the positioning plate and/or latches

Ambient Temperature Range — 10° F (-12.2° C) to 185° F (85° C) ambient at full rated load, up to 220°

F (104° C) ambient with single coil load.

Lever Arm — Die cast zinc construction with hardened, oil-impregnated, sintered iron rollers.

Conduit — 0.5 in. standard / 20 mm optional—Form M11

Mounting — Four baseplates provide end or side mounting holes and/or manifold mounting. All

mounting holes are 0.25 in. (6.35 mm) diameter. Two tapped holes on each side of switch allows side

mounting.

Contacts — SPDT

contact block. Nylon liner. Polarity must be the same on double throw contacts.

1. Single pole, double throw.

1

double break and three point double throw single break. Silver contact tips. Phenolic

9007 (convertible sequence)

9007T Mill Switches

Page 216

9007FT Foundry Switches

Page 218

03/2007

°

C).

Related parts for XCMD2110M12

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Pushbutton, Non-Illum'd Red "STOP", Momentary, 1NO-1NC, Square 30mm, 10A, 600V

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

KITS,TWIDO? PROGRAMMABLE CONTROLLERS,KITS,TWIDOPACK STARTER KIT - ADVANCED LEVEL,PROGRAMMABLE CONTROLLERS,TWIDO? PROGRAMMABLE CONTROLLERS ,SQUARE D

Manufacturer:

SQUARE D

Part Number:

Description:

LAMPS,INDICATOR,STACKABLE,LAMPS, STACKABLE INDICATOR,VISUAL INDICATING SIGNALS,XVB SERIES INDICATING BANKS ,SQUARE D

Manufacturer:

SQUARE D

Part Number:

Description:

LAMPS,INDICATOR,STACKABLE,LAMPS, STACKABLE INDICATOR,VISUAL INDICATING SIGNALS,XVB SERIES INDICATING BANKS ,SQUARE D

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

I/O EXTENDER MODULE 4 D IN & 2 D OUTPUT

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

CB ACCESSORY, UNDERVOLTAGE TRIP 48V DC

Manufacturer:

SQUARE D

Datasheet: