RTV-160 MOMENTIVE PERFORMANCE MATERIALS, RTV-160 Datasheet - Page 35

RTV-160

Manufacturer Part Number

RTV-160

Description

SILICONE 1PART ADH, CART, 10.1FL.OZ

Manufacturer

MOMENTIVE PERFORMANCE MATERIALS

Series

RTV-160r

Datasheet

1.IS-808-2.8.pdf

(40 pages)

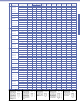

Specifications of RTV-160

Adhesive Type

Silicone - 1 Part

Color

White

Dispensing Method

Cartridge

Volume

10.1fl.oz. (US)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Resistance to ignition

when exposed to high

temperatures. Expressed

as the mean number

of seconds required

to ignite a specimen

when wrapped with an

energized ni-chrome

r e s i s t i v e w i r e t h a t

dissipates a specified

level of energy.

Type

T

TSE3944

TSE3944

TSE3944

TSE3945

TSE3946

TSE397

TSE397

TSE3976-B

TSE3976-B

TSE3976-B

XE11-A5133S

TSE3051-FR

TSE322S

TSE322S

TSE322S

TSE3253

TSE3253

TSE326

TSE326

TSE3260

TSE3260

TSE3260

RTV6428

RTV6428

TSE3331

TSE3331

TSE3331

TSE3331

TSE3331K

TSE3331K

TSE3331K*EX

TSE3331K*EX

TSE3423

TSE3431

TSE3431

TSE3431-H

TSE3431-H

TSE3431-H

TSE3431-H

TSE3664

TSE3664

TSE3664

XE14-B7892

XE14-B7892

SE3944

Grade

HWI

Mean Ignition

Time (sec)

60 - 119

30 - 59

15 - 29

≥ 120

7 - 14

<7

Clear White Black

Clear White Black

Gray White

Gray White

PLC

Color

White

White

White

Black

Black

Black

Clear

Clear

Clear

Clear

Black

Black

Black

Black

Black

Black

Black

Black

Black

Black

Black

Black

0

1

2

3

4

5

Gray

Gray

Gray

Gray

Gray

Gray

Gray

Gray

Gray

Gray

Gray

Gray

Gray

Gray

Red

Red

Red

Red

Red

Ability to withstand

e l e c t r i c a l a r c i n g .

Expressed as the number

of arc rupture exposures

required to ignite a

specimen when the arc

occurs directly on the

surface or a specified

distance above the test

specimen.

Thickness

2.7-3.3

0.75

0.75

0.64

mm

1.5

3.0

3.3

3.0

1.5

3.0

1.5

3.0

3.0

1.0

1.5

3.0

1.3

2.0

1.0

3.0

1.0

2.0

2.6

3.0

6.0

1.0

1.6

2.0

3.0

2.5

3.0

2.5

3.0

3.0

2.0

4.0

1.0

1.5

2.5

3.0

1.0

2.0

3.0

2.0

3.0

HAI

Mean No.

60 - 119

30 - 59

15 - 29

of Arcs

≥ 120

<15

Elec.

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

190

190

190

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

PLC

0

1

2

3

4

RTI

Expressed as the rate

(inches per minute) that

a tracking path can

be produced on the

surface of the material

under standardized test

conditions.

Mech. STR

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

190

190

190

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

105

HVTR

Flame

Class

V-0

V-1

V-0

V-0

V-0

V-1

V-1

V-1

V-1

V-1

V-1

V-0

V-0

V-0

V-0

V-0

V-0

V-0

V-0

V-0

V-1

V-1

V-1

V-0

V-0

V-0

V-0

V-1

V-0

V-0

V-1

V-0

HB

HB

HB

HB

HB

HB

HB

HB

HB

HB

HB

HB

HB

HVTR Range

(in mm/min)

10.1 - 25.4

80.1 - 150

25.5 - 80

0 - 10

>150

(PLC)

HWI

PLC

0

0

2

1

0

0

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0

1

2

3

4

E x p r e s s e d a s t h e

n u m b e r o f s e c o n d s

that a material resists

t h e f o r m a t i o n o f a

surface-conducting path

when subjected to an

intermittently occurring

arc of high voltage, low

current characteristics.

(PLC)

HAI

0

0

0

0

0

0

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

D495

Arc Resistance

360 - 419

300 - 359

240 - 299

180 - 239

120 - 179

HVTR

60 - 119

(PLC)

≥ 420

(sec)

0

0

0

0

0

0

<60

PLC

0

1

2

3

4

5

6

7

D495

(PLC)

3

3

1

0

0

1

E x p r e s s e d a s t h a t

voltage which causes

tracking after 50 drops

o f 0 . 1 % a m m o n i u m

chloride solution have

fallen on the material.

(PLC)

CTI

0

0

0

0

0

1

CTI

Tracking Index

250 - 399

175 - 249

100 - 174

400 -599

(volts)

≥600

<100

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E36952

E36952

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

E56745

File No.

34

PLC

0

1

2

3

4

5