Product Facts

■

■

■

The TE Mated Tool/Terminal

Concept

■

■

■

■

The Crimp

■

■

■

■

Catalog 82004

Revised 3-11

www.te.com

Pre-insulated terminal

designed for complete and

uniform reliability in the

most difficult circuit

environment

Consists of an unplated or

tin plated brass body or a

tin plated phosphor bronze

body with a specially

designed copper sleeve and

insulation sleeve fitted over

the terminal barrel

Design of the tool dies and

construction of the terminal

insures uniform insulation

thickness under crimping

pressure, transmitting this

pressure evenly to the

center of the crimp area

TE compression crimping

produces crimps for a

given size wire and terminal

that are precisely alike

in appearance and

performance

Terminal and the crimping

tool are designed as

precisely matched devices

Dies are precision-

engineered from the finest

hard-metal alloys

Crimping pressure is

controlled by a ratchet

device on the hand tool

or a corresponding pre-

calibration in the crimping

jaws of TE automated

crimping machines

Crimping pressure does not

overstress nor understress

the terminal barrel —

machined dies fully bottom

to the precise crimp height

Resulting termination is

free of contamination

Resistant to most shock and

critical environments

Tensile strength approaches

that of the wire itself

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

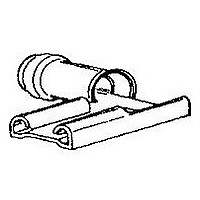

FASTON Terminals (Insulated and Uninsulated)

PIDG FASTON Receptacles and Tabs

Here is a pre-insulated

terminal designed for

complete and uniform

reliability in most difficult

circuit environments. Each

PIDG Terminal consists of a

tin plated brass body with a

specially designed copper

sleeve and insulation sleeve

fitted over the terminal

barrel. The design of the tool

dies and the construction

of the terminal promotes

uniform insulation thickness

under crimping pressure,

transmitting this pressure

evenly to the center of the

crimp area.

Temperature Rating: 105° C

1

UL and CSA — Nylon.

Range

22-16

16-14

12-10

Wire

Dimensions are in inches and

millimeters unless otherwise

specified.

USA: +1 (800) 522-6752

R

22-16 Stranded

16-14 Stranded

12-10 Stranded

Recognized

E66717

TE compression crimping

produces crimps for a

given size wire and terminal

that are precisely alike

in appearance and

performance. This is a

calculated result made

possible by designing the

terminal and the crimping

tool as precisely matched

devices. The dies are

precision-engineered from

the finest hard-metal alloys.

Crimping pressure is

controlled by a ratchet

device on the hand tool or

a corresponding pre-

calibration in the crimping

Canada: +1 (905) 475-6222

Mexico/C. Am.: +52 (0) 55-1106-0800

Latin/S. Am.: +54 (0) 11-4733-2200

Germany: +49 (0) 6251-133-1999

105°C Max.

300 V Max.,

R

Certified

LR7189

1

jaws of TE automated

crimping machines.

Crimping pressure can

neither over-stress nor

understress the terminal

barrel — machined dies

fully bottom to the precise

crimp height required.

The resulting termination

is free of contamination,

is resistant to shock and

critical environments,

and its tensile strength

approaches that of the

wire itself.

UK: +44 (0) 800-267666

France: +33 (0) 1-3420-8686

Netherlands: +31 (0) 73-6246-999

China: +86 (0) 400-820-6015

99