171662-1 TE Connectivity, 171662-1 Datasheet - Page 32

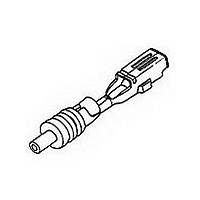

171662-1

Manufacturer Part Number

171662-1

Description

E-J MK-2 070 REC CONT

Manufacturer

TE Connectivity

Type

Contactr

Series

070r

Datasheet

1.171662-1.pdf

(80 pages)

Specifications of 171662-1

Gender

RCP

Body Orientation

Straight

Housing Material

Not Required

Number Of Contacts

1POS

Number Of Ports

1Port

Number Of Terminals

1

Pitch (mm)

Not Requiredmm

Contact Material

Brass

Operating Temp Range

-30C to 105C

Mounting Style

Cable

Termination Method

Crimp

Contact Plating

Pre-Tin

Product Height (mm)

3.6mm

Product Depth (mm)

5.4mm

Product Length (mm)

16.5mm

Product Line

Econoseal J

Product Type

Contact

Wire/cable Type

Discrete Wire

Cable Type

Thin Wall

Termination Method To Wire/cable

Crimp

Wire/cable Size (awg)

16 – 20

Wire/cable Size (mm²)

0.5 – 1.25

Wire Type

Stranded

Contact Type

Socket

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Pre-Tin

Contact Plating, Mating Area, Thickness (µm [?in])

0.76 [29.92]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

2.00 – 2.60 [0.079 – 0.102]

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Reel

Packaging Quantity

6000

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

171662-1

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

171662-1

Manufacturer:

TE/TYCO

Quantity:

6 600

32

AMP Sealed Connectors

A

Contacts

Wire Seals

Connector Housings

Available in 1.5 mm [.059 in.]

and 2.5 mm [.098 in. ] pin

diameters.

Available with either tin,

silver or gold plating.

Rugged two piece

construction with stainless

steel jacket allows the use

of optimized (CuNiSi)

contact material.

Six points of contact (2.5 mm

System) and five points of

contact (1.5 mm System)

2.5 mm System wire range

0.2 - 2.5 mm

AWG.

1.5 mm System wire range

0.2 - 2.5 mm

AWG.

Made from silicon rubber

material.

Wire seal is crimped

simultaneously with the

contact.

2.5 mm System accomodates

insulation diameters of

1.2 - 3.0 mm [.047 - .118 in.].

1.5 mm System accomodates

insulation diameters of

1.2 - 3.0 mm [.047 - .118 in.]

Made from glass filled PBT

material.

2.5 mm System will mate to

customer interfaces made

per DIN 72585.

Pre-assembled interface

and panel mounting seal.

The 2.5 mm System is

available in 4 position or in

2 and 3 positions with

blocked cavities. Four

keying options are

available per position size.

The 1.5 mm System is

available only in a 7

position version.

2

2

[#24 - #14]

[#24 - #14]

AMP Technical Support Center/AMP FAX Service

1-800-522-6752 717-986-7777

AMP Sealed Connectors

Sealed Circular Connectors . . . 2.5mm and 1.5mm Systems

AMP in conjunction with

major European truck

manufacturers has

developed a standard

system of circular sealed

connectors to meet the

demand for superior

performance under

environments of extreme

vibration, physical shock

and temperature change.

Typical applications include

magnetic valves, sensors

for ABS and powertrain

management (including

direct engine mounting)

and lighting.

The 2.5 mm System uses a

standard outer shell which

can be supplied in either

2 or 3 position versions with

the extra cavities blocked

or in a 4 position version.

Each position size is

available with four different

keying options that are

designated by color code.

The 1.5 mm System uses

the same outer shell but is

available only in a 7

position version.

The shell standardization

allows the use of the same

back shells for all parts.

Back shells are available in

90° and 180° wire exit

versions with the options for

mounting 8.5 mm or 10 mm

convoluted tubing or the

use of our adjustable strain

relief feature on the free

wire version.

The housings are available

as free hanging male and

female connectors or for

mating to a customer

supplied pin interface

according to DIN 72585,

Part 1 (ISO 15170

pending). The free hanging

pin housing is also suitable

for through panel mounting

and is supplied with a pre-

assembled seal for panel

sealing. The actual

mounting is achieved with

the use of a separately

available locking ring.

Terminal construction is

of a two piece design to

allow optimization of

electrical and mechanical

performance. An outer

stainless steel jacket pro-

vide protection against

handling damage.

Dimensions are in

millimeters over [inches]

www.amp.com

Product Performance

Temperature Rating

For tin plating -40° to 130° C

For silver plating -40° to 140° C

For gold plating -40° to 150° C

Dielectric Strength

1.0 kVAC between adjacent contact or to

shell

Contact Termination Resistance

5 m Max. (Initial)

10 m Max. (Final)

Current Guidelines (Map Wire Size)

2.5 mm . . . 30 amps Max.

1.5 mm . . . 25 amps Max.

(Using the maximum wire size at 23°C)

Product Documentation

Product Specification

108-18621

108-18027, DIN 72585 (2.5 mm)

108-18028 (1.5 mm)

Application Specification

114-18255

114-18020 (2.5 mm)

114-18040 (1.5 mm)

Specifications

subject to change.

Revised 01-00

Catalog

65481