1241381-1 TE Connectivity, 1241381-1 Datasheet

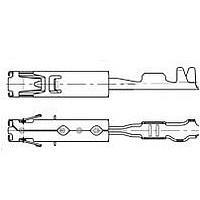

1241381-1

Manufacturer Part Number

1241381-1

Description

MCP1.5 SOCKET CONTACT SWS

Manufacturer

TE Connectivity

Series

HDSCS, Multiple Contact Point (MCP)r

Datasheet

1.1241381-1.pdf

(100 pages)

Specifications of 1241381-1

Product Type

Contact

Mating Area Interface Dimensions (mm [in])

1.50 x 0.60 [.059 x .024]

Wire/cable Type

Regular Wire

Insulation Support

With

Wire Range (mm [awg])

0.50-1.00² [20-17]

Single Wire Sealing System

Yes

Insulation Type

FLR (Thin Walled Cable)

Cantilever Spring Material

Stainless Steel

Contact Type

Socket

Contact Base Material

CuNiSi

Contact Plating, Mating Area, Material

Pre-Tin

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Accepts Wire Insulation Diameter, Range (mm [in])

1.40 – 2.10 [0.055 – 0.083]

Applies To

Wire/Cable

Packaging Method

Loose Piece

Packaging Quantity

500

AMP MCP offers

High Reliability for

Long Term Use

AMP MCP Interconnection System

AMP MCP 1.5K Contact System

Introduction

The AMP MCP (Multiple Con-

tact Point) Connector System

is designed for electronic

and electrical applications in

motor vehicles.

It fullfils all requirements for

a connector system for use

in automobiles and covers a

wide range of applications.

All specifications subject to change. Consult Tyco Electronics for latest specifications.

AMP MCP Contacts

I

I

I

I

I

I

I

Basic material (CuNiSi) with

high current capacity

3 redundant contact points

(1.5 mm type), 4 contact

points (2.8 mm/6.3 mm

type), 6 contact points

(9.5 mm type)

Good guiding inside the

cavity

Protected contact spring

due to the closed box

Overstress protection of the

contact springs

Steel box with secondary

locking possibility from four

sides

Protected locking lance

AMP MCP Connectors

I

I

I

I

I

I

I

I

High reliability status

supported for long term use

High vibration level

supported

Perfect design to avoid

quality problems, reduce

manufacturing and service

cost

Integrated secondary

locking device delivered in

pre-locked position

Wire-to-wire sealed and

unsealed connectors (SWS)

Wire-to-board sealed and

unsealed connectors (SWS)

Polarisation, several keyings

Locking mechanism for

smaller connectors/mating

aid for higher numbers of

ways

Main Catalog 1654400-1

Chapter 3 – Issued

Revised

12-2009.

3-2010.

3-1