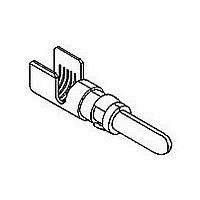

213841-2 TE Connectivity, 213841-2 Datasheet

213841-2

Specifications of 213841-2

Available stocks

Related parts for 213841-2

213841-2 Summary of contents

Page 1

... Design and Construction Product shall be of the design, construction and physical dimensions specified on the applicable product drawing. ©2011 Tyco Electronics Corporation, | Indicates change a TE Connectivity Ltd. Company *Trademark All Rights Reserved TE logo is a trademark. For latest revision, visit our website at www.te.com/documents. ...

Page 2

Materials Materials used in the construction of this product shall be as specified on the applicable product drawing. 3.3. Ratings ! Voltage: 30 volts AC ! Current: Signal application only, 0.5 ampere maximum per single circuit ! Temperature: -65 ...

Page 3

Test Description Mechanical shock. Durability (receptacles). Mating force (receptacles). Unmating force (receptacles). Thermal shock. Humidity-temperature cycling. Temperature life. Mixed flowing gas (receptacles). Shall meet visual requirements, show no physical damage, and meet requirements of additional NOTE tests as specified in ...

Page 4

Product Qualification and Requalification Test Sequence Test or Examination Initial examination of product Low level contact resistance Insulation resistance Withstanding voltage Vibration Mechanical shock Durability Mating force Unmating force Thermal shock Humidity-temperature cycling Temperature life Mixed flowing gas Final ...

Page 5

Acceptance Acceptance is based on verification that the product meets the requirements of Figure 1. Failures attributed to equipment, test setup or operator deficiencies shall not disqualify the product. If product failure occurs, corrective action shall be taken and ...

Page 6

No straight posted header is required with Paddleboard which solders directly to the NOTE printed circuit board. Vibration & Mechanical Shock Mounting Fixture Rev B Figure 4 108-1109 ...