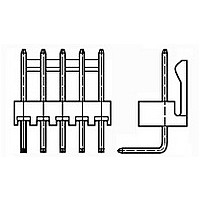

3-647630-9 TE Connectivity, 3-647630-9 Datasheet

3-647630-9

Specifications of 3-647630-9

Related parts for 3-647630-9

3-647630-9 Summary of contents

Page 1

... General Requirements for Test Specifications ! 109 Series: Test Specifications as indicated in Figure 1 ! 114-1019: Application Specification ! 501-366: Qualification Test Report 3. REQUIREMENTS 3.1. Design and Construction Product shall be of design, construction and physical dimensions specified on the applicable product drawing. 3.2. ...

Page 2

... ELECTRICAL 6 milliohms maximum initial. ∆R 10 milliohms maximum. 5000 megohms minimum initial. 750 vac at sea level. 1 minute hold with no breakdown or flashover. 30° C maximum temperatur e rise at specified current. MECHANICAL Solderable area shall have minimum of 95% solder coverage. Wire Size Slot Tensile AWG ...

Page 3

... Figure 1 (end) 108-1050 Procedure TE Spec 109-21-1. Subject mated samples to 10-55-10 Hz traversed in 1 minute at .06 inch total excursion. 2 hours in each of 3 mutually perpendicular planes. TE Spec 109-26-1. Subject mated samples to 50 G's half-sine shock pulses of 11 milliseconds duration. 3 shocks in each direction applied along 3 mutually perpendicular planes, 18 total shocks ...

Page 4

... Subject half the samples to the parallel tensile test and the remaining half to the perpendicular tensile test. (g) Precondition samples with 5 cycles durability. Rev H Test Group (a) 1 2(c) 3( Test Sequence (b) 1,9 1,9 1,5 1,8 1,3 3,7 2,7 2,4 2,6 3,7 3,8 2( level for 100% loadings per Figure 2 108-1050 6 1 ...

Page 5

... PN 93-660652; and 3, 10 position standard tin-lead plated samples terminated to 22 AWG wire and mounted on printed circuit board PN 93-660651 (see Figure 5). Test group 3 shall consist position gold plated samples terminated to 22 AWG wire and mounted on printed circuit board PN 93-660017. Test group 4 shall consist of 5 unmounted 24 position standard tin-lead plated samples terminated to the maximum wire size ...

Page 6

... Termination resistance equals millivolts divided by test current less resistance of 2 NOTE inches of wire. (b) After wave soldering, the boards and posts shall be cleaned to remove all flux and contaminates. Temperature & Termination Resistance Measurement Points Rev H Figure 3 108-1050 ...

Page 7

... NOTE gage indicated, use the Multiplication Factor (F) from the above chart and multiply it times the Base Rated Current for a single circuit at maximum ambient operating temperature as shown in Figure 4A. Rev H Figure 4A Current Carrying Capability Wire Size AWG 100 .3 .4 Figure 4B Current Rating 108-1050 1 ...

Page 8

PC Board Used For Termination Resistance Dry Circuit Rev H PC Board Used For Current Rating Figure 5 Printed Circuit Test Boards 108-1050 ...

Page 9

Rev H Figure 6 Termination Tensile Strength 108-1050 ...