32-3572-11 Aries Electronics, 32-3572-11 Datasheet

32-3572-11

Manufacturer Part Number

32-3572-11

Description

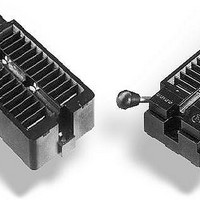

IC & Component Sockets 32P ZIF SOCKET GOLD

Manufacturer

Aries Electronics

Datasheet

1.32-6574-10.pdf

(2 pages)

Specifications of 32-3572-11

Product

Zero Insertion Force (ZIF) Sockets

Pitch

2.54 mm

Number Of Rows

2

Number Of Positions / Contacts

32

Contact Plating

Gold Over Nickel

Mounting Style

Through Hole

Termination Style

Solder Tail

Features

Solder into PCBs or Plugged

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

FEATURES

GENERAL SPECIFICATIONS

MOUNTING CONSIDERATIONS

• Universal Test Socket accepts devices on 0.300 to 0.600 [7.62 to 15.24] centers

• All pin count sockets go into PCB with either 0.300 or 0.600 [7.62 to 15.24] centers

• Swing quick-release handle down to open contacts and insert device. Release and

• Socket handle can be mounted on either the right or left side

• Sockets can be soldered into PCBs or plugged into any socket

• STANDARD SOCKET BODY: (for -10, -10TL, -11, -16 sockets) black UL 94V-0

• HIGH-TEMPERATURE SOCKET BODY: (for -18 socket) natural color Poly-

• HANDLE: Stainless Steel

• HANDLE KNOB: Brass 360, 1/2-hard (no knob on loop handle)

• CONTACT MATERIAL: (for -10, -10TL, -11) BeCu 172 per QQ-C-553; (for -16)

• ALL BECU CONTACTS: 50μ [1.27μ] min. Ni under plate per QQ-N-290, over plated with either: -10 200μ [5.08μ] min. matte

• SPINODAL CONTACT PLATING: (for -16) 50μ [1.27μ] min. NiB

• HIGH-TEMPERATURE BeNi CONTACT PLATING:

• CONTACT CURRENT RATING: 1 amp

• INSULATION RESISTANCE: 1000 mΩ min.

• DIELECTRIC WITHSTANDING VOLTAGE: 1000

• LIFE CYCLE: 25,000 to 50,000 cycles

• OPERATING TEMPERATURE: min. -67°F

• RETENTION FORCE (closed): 55 grams/pin

• ACCEPTS LEADS: 0.015-0.035 [0.38-0.89]

• See socket footprint below

handle automatically returns as contacts close onto device leads

glass-filled Polyphenylene Sulfide (PPS)

etheretherketone (PEEK)

Spinodal; (for -18) BeNi 360, 1/2-hard

Sn per ASTM B545-97; or -10TL 200μ [5.08μ] min. 90/10 Sn/Pb per MIL-T-10727-11 10μ [0.25μ] min. Au per MIL-G-45204

(for -18) 50μ [1.27μ] NiB

VAC

[-55°C]; max. 221°F [105°C] for

Sn plating, 302°F [150°C] for Au plating, 392°F

[200°C] for NiB plating,

482°F [250°C] for high-temperature socket

based on a 0.020 [0.51] dia. test lead

wide, 0.110-0.280 [2.79-7.11] long

PRINTOUTS OF THIS DOCUMENT MAY BE OUT OF DATE AND SHOULD BE CONSIDERED UNCONTROLLED

Series X57X Quick-Release Universal

Zero-Insertion-Force DIP Test Socket

Bristol, PA 19007-6810 USA

TEL (215) 781-9956 • FAX (215) 781-9845

WWW.ARIESELEC.COM

Pins

Row-to-Row Spacing (btm)

• INFO@ARIESELEC.COM

24, 28, 32, 36,

40, 42, 44, 48

3 = 0.300 [7.62]

6 = 0.600 [15.24] (std)

ORDERING INFORMATION

XX-X57X-1 8

Loop (no Knob)

Short w/ Knob

Long w/Knob

Handle

CUSTOMIZATION: In addition to the standard products shown

on this page, Aries specializes in custom design and production.

Special materials, platings, sizes, and configurations can be

furnished, depending on the quantity. NOTE: Aries reserves the

right to change product general specifications without notice.

Plating

Solder Pin Tail

45° Handle Options

* NOTE: only Loop Handle available

0.270 [6.86]

0.568 [14.43]

0.317 [8.05]

w/hi-temp. socket

Dim “H1”

OTL = Sn/Pb over Ni

0 = Sn over Ni

1 = Ay over Ni

6 = NiB (Spinodal)

8 = Hi-temp

0 = Long Handle, right side

1 = Long Handle, left side

2 = Short Handle, right side

3 = Short Handle, left side

4 = Loop Handle, right side

5 = Loop Handle, left side

0.400 [10.16]

0.193 [4.90]

0.300 [7.62]

Dim. “H2”

Socket*

0.405 [10.29]

0.471 [11.96]

0.252 [6.40]

Dim “H3”

Rev. AA

10019

1 of 2

Related parts for 32-3572-11

32-3572-11 Summary of contents

Page 1

... MOUNTING CONSIDERATIONS • See socket footprint below PRINTOUTS OF THIS DOCUMENT MAY BE OUT OF DATE AND SHOULD BE CONSIDERED UNCONTROLLED ORDERING INFORMATION Pins 24, 28, 32, 36, 40, 42, 44, 48 Row-to-Row Spacing (btm 0.300 [7.62 0.600 [15.24] (std) Bristol, PA 19007-6810 USA TEL (215) 781-9956 • FAX (215) 781-9845 WWW.ARIESELEC.COM • ...

Page 2

Series X57X Quick-Release Universal Zero-Insertion-Force DIP Test Socket ALL DIMENSIONS: INCHES [MILLIMETERS] ALL TOLERANCES: ±0.005 [0.13] UNLESS OTHERWISE SPECIFIED “A” = (NO. OF PINS PER ROW x 0.100 [2.54]) + 0.590 [14.99] “B” = (NO. OF PINS PER ROW -1) ...