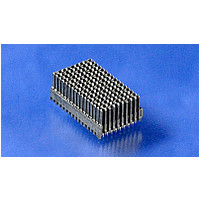

1410210-1 TE Connectivity, 1410210-1 Datasheet

1410210-1

Specifications of 1410210-1

Related parts for 1410210-1

1410210-1 Summary of contents

Page 1

SCOPE 1.1. Content This specification covers perform ance, tests and quality requirem ents for the Tyco Electronics MULTIGIG RT* Signal connector system which uses a m odular concept and interconnects two printed circuit boards. Both receptacle and ...

Page 2

REQUIREM ENTS 3.1. Design and Construction Product shall be of the design, construction and physical dim ensions specified on the applicable product drawing. 3.2. Materials Materials used in the construction of this product shall be as specified on the ...

Page 3

Test Description W ithstanding voltage. Tem perature rise vs current. Vibration, sinusoidal. Mechanical shock. Durability. Mating force. Unm ating force. Com pliant pin insertion. Com pliant pin retention. Rev D Requirem ent 1 m inute hold with no breakdown or ...

Page 4

Test Description Minute disturbance. Therm al shock. Hum idity/tem perature cycling. Tem perature life. Mixed flowing gas. Dust contam ination. Shall meet visual requirements, show no physical damage, and meet requirements of additional NOTE tests as specified in the Product ...

Page 5

Product Qualification and Requalification Test Sequence A. Tier 1 Product Test or Examination Initial examination of product Low level contact resistance, circuit Low level contact resistance, compliant pin (c) Insulation resistance Withstanding voltage Temperature rise vs current Vibration Mechanical ...

Page 6

B. Tier 2 Product Test or Examination Initial examination of product Low level contact resistance, circuit Low level contact resistance, compliant pin (c) Insulation resistance Withstanding voltage Temperature rise vs current Vibration Mechanical shock Durability Mating force Unmating force Compliant ...

Page 7

C. RT2 Mezzanine Product | | | | Test or Exam ination | | | | | Initial exam ination of product | | | Low level contact resistance, circuit | | | Vibration | | | Mechanical shock ...

Page 8

QUALITY ASSURANCE PROVISIONS 4.1. Qualification Testing A. Specim en Selection 1. Tier 1 Product Specim ens shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. Each test group shall consist ...

Page 9

Quality Conform ance Inspection The applicable quality inspection plan shall specify the sam pling acceptable quality level to be used. Dim ensional and functional requirem ents shall be in accordance with the applicable product drawing and this specification. Rev ...

Page 10

Low Level Contact Resistance Measurem ent Points (Circuit) Low Level Contact Resistance Measurem ent Points (Com pliant Pin) Rev D Figure 3 Figure 4 108-2072 ...