A3952SB Allegro Micro Systems, Inc., A3952SB Datasheet

A3952SB

Available stocks

Related parts for A3952SB

A3952SB Summary of contents

Page 1

... LOGIC SUPPLY PHASE ENABLE 8 9 Note that the A3952SB (DIP) and the A3952SLB (SOIC) are electrically identical and share a common terminal number assignment. Load Supply Voltage, V .................. Output Current, I OUT ( .................................. w (Continuous) ............................... Logic Supply Voltage, V ................. 7.0 V ...

Page 2

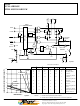

FULL-BRIDGE PWM MOTOR DRIVER SLEEP & STANDBY MODES MODE PHASE ENABLE BRAKE LOGIC V CC SUPPLY REF 1 GROUND 10 'B' , 'EB', & 'LB' TAB 8 6 'W' AMBIENT 4 'B' & 'EB' AMBIENT 'LB' ...

Page 3

FULL-BRIDGE PWM MOTOR DRIVER 5 GROUND LOGIC GROUND Characteristic Output Drivers Load Supply Voltage Range Output Leakage Current Output Saturation Voltage Clamp Diode Forward Voltage (Source or Sink) Load ...

Page 4

FULL-BRIDGE PWM MOTOR DRIVER Characteristic Control Logic Logic Supply Voltage Range Logic Input Voltage Logic Input Current Reference Voltage Range Reference Input Current Reference Voltage Divider Ratio Comparator Input Offset Voltage PWM RC Fixed OFF Time PWM Minimum ON ...

Page 5

FULL-BRIDGE PWM MOTOR DRIVER INTERNAL PWM CURRENT CONTROL DURING FORWARD AND REVERSE OPERATION The A3952S– contains a fixed OFF-time pulse-width modulated (PWM) current-control circuit that can be used to limit the load current to a desired value. The value ...

Page 6

FULL-BRIDGE PWM MOTOR DRIVER Brake Operation - MODE Input Low During braking, with the MODE input low, the peak current limit defaults internally to a value approximated 1.5 V/R TRIP In this mode, the value of ...

Page 7

FULL-BRIDGE PWM MOTOR DRIVER The following procedure can be used to evaluate the worst-case slow-decay internal PWM load current regula- tion in the system: Set volts. With the load connected and the PWM REF current control ...

Page 8

FULL-BRIDGE PWM MOTOR DRIVER imply that output short circuits are permitted. The hyster- esis of the thermal shutdown circuit is approximately the internal current-control circuitry is not used; the V terminal should be connected to V ...

Page 9

FULL-BRIDGE PWM MOTOR DRIVER PCB Layout The load supply terminal (>47 F electrolytic and 0.1 F ceramic capacitors are recommended) as close to the device as is physically practical. To minimize the effect of system ground I•R ...

Page 10

FULL-BRIDGE PWM MOTOR DRIVER motor is more linear than in the case of ENABLE PWM control (which produces a discontinuous current at low- current levels). With bidirectional dc servo motors, the PHASE termi- nal can be used for mechanical ...

Page 11

FULL-BRIDGE PWM MOTOR DRIVER 16 0.280 0.240 1 0.070 0.045 0.210 MAX 0.015 MIN 0.022 0.014 7.11 6.10 5.33 MAX NOTES: 1. Leads and 16 may be half leads at vendor’s option. 2. Webbed lead frame. ...

Page 12

FULL-BRIDGE PWM MOTOR DRIVER NOTES: 1. Index is centered on “D” side. 2. Webbed lead frame. Leads indicated are internally one piece. 3. Lead spacing tolerance is non-cumulative. 4. Exact body and lead configuration at vendor’s option within limits ...

Page 13

FULL-BRIDGE PWM MOTOR DRIVER 0.2992 0.2914 0.020 0.013 0.0926 0.1043 7.60 7.40 0.51 0.33 2.65 2.35 NOTES: 1. Webbed lead frame. Leads indicated are internally one piece. 2. Lead spacing tolerance is non-cumulative. 3. Exact body and lead configuration ...

Page 14

FULL-BRIDGE PWM MOTOR DRIVER INDEX AREA 0.065 0.035 INDEX AREA 1.65 0.89 NOTES: 1. Lead thickness is measured at seating plane or below. 2. Lead spacing tolerance is non-cumulative. 3. Exact body and lead configuration at vendor’s option within ...

Page 15

FULL-BRIDGE PWM MOTOR DRIVER ...

Page 16

FULL-BRIDGE PWM MOTOR DRIVER Allegro MicroSystems, Inc. reserves the right to make, from time to time, such departures from the detail specifications as may be required to permit improvements in the design of its products. The information included herein ...