IR3094M International Rectifier Corp., IR3094M Datasheet - Page 25

IR3094M

Manufacturer Part Number

IR3094M

Description

3 Phase Pwm Controller For Point Of Load

Manufacturer

International Rectifier Corp.

Datasheet

1.IR3094M.pdf

(29 pages)

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

IR3094MPBF

Manufacturer:

IOR

Quantity:

331

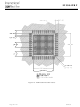

PCB AND STENCIL DESIGN METHODOLOGY

x

x

x

See Figures 10-12.

PCB Metal Design (0.5mm Pitch Leads)

1.

spacing should be

2.

0.05mm inboard extension. The outboard extension ensures a large and inspectable toe fillet, and the

inboard extension will accommodate any part misalignment and ensure a fillet.

3.

the minimum metal to metal spacing should be

and

4.

connected to ground to minimize the noise effect on the IC, and to transfer heat to the PCB.

PCB Solder Resist Design (0.5mm Pitch Leads)

1.

of 0.060mm. The solder resist mis-alignment is a maximum of 0.050mm and it is recommended that

the lead lands are all NSMD. Therefore pulling the S/R 0.060mm will always ensure NSMD pads.

2.

is completely removed from between the lead lands forming a single opening for each “group” of lead

lands.

3.

provide a fillet so a solder resist width of

4.

copper of 0.060mm to accommodate solder resist mis-alignment. In 0.5mm pitch cases it is allowable

to have the solder resist opening for the land pad to be smaller than the part pad.

5.

the high aspect ratio of the solder resist strip separating the lead lands from the pad land.

6.

larger than the diameter of the via.

Stencil Design (0.5mm Pitch Leads)

1.

lands. Reducing the amount of solder deposited will minimize the occurrence of lead shorts. Since for

0.5mm pitch devices the leads are only 0.25mm wide, the stencil apertures should not be made

narrower; openings in stencils < 0.25mm wide are difficult to maintain repeatable solder release.

2.

on the lead land.

3.

deposit approximately 50% area of solder on the center pad. If too much solder is deposited on the

center land pad the part will float and the lead lands will be open.

4.

solder resist opening minus an annular 0.2mm pull back to decrease the incidence of shorting the

center land to the lead lands when the part is pushed into the solder paste.

Page 25 of 29

7x7

48 Lead

0.5mm pitch MLPQ

Lead land width should be equal to nominal part lead width. The minimum lead to lead

Lead land length should be equal to maximum part lead length + 0.2 mm outboard extension +

Center pad land length and width should be = maximum part pad length and width. However,

Sixteen 0.30mm diameter vias shall be placed in the pad land spaced at 1.2mm, and

Lead lands. The solder resist should be pulled away from the metal lead lands by a minimum

The minimum solder resist width is 0.13mm, therefore it is recommended that the solder resist

At the inside corner of the solder resist where the lead land groups meet, it is recommended to

Land Pad. The land pad should be SMD, with a minimum overlap of the solder resist onto the

Ensure that the solder resist in-between the lead lands and the pad land is

The single via in the land pad should be tented with solder resist 0.4mm diameter, or 0.1mm

The stencil apertures for the lead lands should be approximately 80% of the area of the lead

The stencil lead land apertures should therefore be shortened in length by 80% and centered

The center land pad aperture should be striped with 0.25mm wide openings and spaces to

The maximum length and width of the center land pad stencil aperture should be equal to the

IR3094PBF

09/26/05