VIPER53ESPTR-E STMicroelectronics, VIPER53ESPTR-E Datasheet - Page 10

VIPER53ESPTR-E

Manufacturer Part Number

VIPER53ESPTR-E

Description

IC OFFLINE SWIT PWM POWERSO10

Manufacturer

STMicroelectronics

Series

VIPER™r

Datasheet

1.VIPER53ESPTR-E.pdf

(31 pages)

Specifications of VIPER53ESPTR-E

Output Isolation

Isolated

Frequency Range

93 ~ 300kHz

Voltage - Input

8.4 ~ 19 V

Voltage - Output

620V

Power (watts)

40W

Operating Temperature

25°C ~ 125°C

Package / Case

PowerSO-10 Exposed Bottom Pad

On Resistance (max)

1.7 Ohms

Supply Voltage (max)

19 V

Supply Voltage (min)

2.6 V

Maximum Operating Temperature

+ 150 C

Minimum Operating Temperature

- 40 C

Mounting Style

SMD/SMT

Number Of Switches

Single

Off Isolation (typ)

8.4 V

Operating Temperature (max)

150C

Operating Temperature (min)

-40C

Pin Count

10

Mounting

Surface Mount

Package Type

PowerSO

Screening Level

Automotive

For Use With

497-8435 - BOARD EVAL FOR VIPER53 28W497-6458 - BOARD EVAL BASED ON VIPER53-E497-6262 - BOARD REF SGL VIPER53 90-264VAC497-5866 - EVAL BOARD 24W NEG OUT VIPER53E497-5865 - EVAL BOARD 24W POS OUT VIPER53E497-4933 - BOARD PWR SUPPLY 24W OUTPUT VIPE

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

497-5772-2

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

VIPER53ESPTR-E

Manufacturer:

TI

Quantity:

1 500

Part Number:

VIPER53ESPTR-E

Manufacturer:

ST

Quantity:

20 000

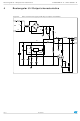

Current Mode Topology

6

10/31

Current Mode Topology

The VIPer53E implements the conventional current mode control method for regulating the

output voltage. This kind of feedback includes two nested regulation loops:

The inner loop controls the peak primary current cycle by cycle. When the Power MOSFET

output transistor is on, the inductor current (primary side of the transformer) is monitored

with a SenseFET technique and converted into a voltage. When V

power switch is turned off. This structure is completely integrated as shown on the Block

Diagram of

time function and the PWM latch. The following formula gives the peak current in the Power

MOSFET according to the compensation voltage:

The outer loop defines the level at which the inner loop regulates peak current in the power

switch. For this purpose, V

optocoupler in secondary feedback configuration, see

accordingly the peak drain current for each switching cycle.

As the inner loop regulates the peak primary current in the primary side of the transformer,

all input voltage changes are compensated for before impacting the output voltage. This

results in an improved line regulation, instantaneous correction to line changes, and better

stability for the voltage regulation loop.

Current mode topology also provides a good converter start-up control. The compensation

voltage can be controlled to increase slowly during the start-up phase, so the peak primary

current will follow this soft voltage slope to provide a smooth output voltage rise, without any

overshoot. The simpler voltage mode structure which only controls the duty cycle, leads

generally to high current at start-up with the risk of transformer saturation.

An integrated blanking filter inhibits the PWM comparator output for a short time after the

integrated Power MOSFET is switched on. This function prevents anomalous or premature

termination of the switching pulse in the case of current spikes caused by primary side

transformer capacitance or secondary side rectifier reverse recovery time when working in

continuous mode.

Figure on page

COMP

1, with the current amplifier, the PWM comparator, the blanking

I

is driven by the feedback network (TL431 through an

Dpeak

DocRev1

=

V

------------------------------------------------- -

COMP

H

COMP

–

V

COMPos

Figure 3 on page

VIPer53EDIP - E / VIPer53ESP - E

S

reaches V

8) and is sets

COMP

, the