LM2575S-12/NOPB National Semiconductor, LM2575S-12/NOPB Datasheet - Page 18

LM2575S-12/NOPB

Manufacturer Part Number

LM2575S-12/NOPB

Description

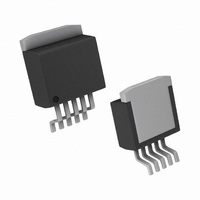

IC REG SIMPLE SWITCHER TO-263-5

Manufacturer

National Semiconductor

Series

SIMPLE SWITCHER®r

Type

Step-Down (Buck)r

Datasheet

1.LM2575S-5.0NOPB.pdf

(28 pages)

Specifications of LM2575S-12/NOPB

Internal Switch(s)

Yes

Synchronous Rectifier

No

Number Of Outputs

1

Voltage - Output

12V

Current - Output

1A

Frequency - Switching

52kHz

Voltage - Input

4 ~ 40 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Surface Mount

Package / Case

D²Pak, TO-263 (5 leads + tab)

Primary Input Voltage

25V

No. Of Outputs

1

Output Voltage

12V

Output Current

1A

No. Of Pins

5

Operating Temperature Range

-40°C To +125°C

Msl

MSL 3 - 168 Hours

Supply Voltage Range

4V To 40V

Rohs Compliant

Yes

Filter Terminals

SMD

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Power - Output

-

Other names

*LM2575S-12

*LM2575S-12/NOPB

LM2575S-12

*LM2575S-12/NOPB

LM2575S-12

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

www.national.com

Application Hints

INPUT CAPACITOR (C

To maintain stability, the regulator input pin must be bypassed

with at least a 47 μF electrolytic capacitor. The capacitor's

leads must be kept short, and located near the regulator.

If the operating temperature range includes temperatures be-

low −25°C, the input capacitor value may need to be larger.

With most electrolytic capacitors, the capacitance value de-

creases and the ESR increases with lower temperatures and

age. Paralleling a ceramic or solid tantalum capacitor will in-

crease the regulator stability at cold temperatures. For maxi-

mum capacitor operating lifetime, the capacitor's RMS ripple

current rating should be greater than

INDUCTOR SELECTION

All switching regulators have two basic modes of operation:

continuous and discontinuous. The difference between the

two types relates to the inductor current, whether it is flowing

continuously, or if it drops to zero for a period of time in the

normal switching cycle. Each mode has distinctively different

operating characteristics, which can affect the regulator per-

formance and requirements.

The LM2575 (or any of the Simple Switcher family) can be

used for both continuous and discontinuous modes of oper-

ation.

The inductor value selection guides in Figure 3 through Figure

7 were designed for buck regulator designs of the continuous

inductor current type. When using inductor values shown in

the inductor selection guide, the peak-to-peak inductor ripple

current will be approximately 20% to 30% of the maximum DC

current. With relatively heavy load currents, the circuit oper-

ates in the continuous mode (inductor current always flowing),

but under light load conditions, the circuit will be forced to the

discontinuous mode (inductor current falls to zero for a period

of time). This discontinuous mode of operation is perfectly

acceptable. For light loads (less than approximately 200 mA)

it may be desirable to operate the regulator in the discontin-

uous mode, primarily because of the lower inductor values

required for the discontinuous mode.

The selection guide chooses inductor values suitable for con-

tinuous mode operation, but if the inductor value chosen is

prohibitively high, the designer should investigate the possi-

bility of discontinuous operation. The computer design soft-

ware Switchers Made Simple will provide all component

values for discontinuous (as well as continuous) mode of op-

eration.

Inductors are available in different styles such as pot core,

toriod, E-frame, bobbin core, etc., as well as different core

materials, such as ferrites and powdered iron. The least ex-

pensive, the bobbin core type, consists of wire wrapped on a

ferrite rod core. This type of construction makes for an inex-

pensive inductor, but since the magnetic flux is not completely

contained within the core, it generates more electromagnetic

interference (EMI). This EMI can cause problems in sensitive

IN

)

18

circuits, or can give incorrect scope readings because of in-

duced voltages in the scope probe.

The inductors listed in the selection chart include ferrite pot

core construction for AIE, powdered iron toroid for Pulse En-

gineering, and ferrite bobbin core for Renco.

An inductor should not be operated beyond its maximum rat-

ed current because it may saturate. When an inductor begins

to saturate, the inductance decreases rapidly and the inductor

begins to look mainly resistive (the DC resistance of the wind-

ing). This will cause the switch current to rise very rapidly.

Different inductor types have different saturation characteris-

tics, and this should be kept in mind when selecting an in-

ductor.

The inductor manufacturer's data sheets include current and

energy limits to avoid inductor saturation.

INDUCTOR RIPPLE CURRENT

When the switcher is operating in the continuous mode, the

inductor current waveform ranges from a triangular to a saw-

tooth type of waveform (depending on the input voltage). For

a given input voltage and output voltage, the peak-to-peak

amplitude of this inductor current waveform remains constant.

As the load current rises or falls, the entire sawtooth current

waveform also rises or falls. The average DC value of this

waveform is equal to the DC load current (in the buck regu-

lator configuration).

If the load current drops to a low enough level, the bottom of

the sawtooth current waveform will reach zero, and the

switcher will change to a discontinuous mode of operation.

This is a perfectly acceptable mode of operation. Any buck

switching regulator (no matter how large the inductor value is)

will be forced to run discontinuous if the load current is light

enough.

OUTPUT CAPACITOR

An output capacitor is required to filter the output voltage and

is needed for loop stability. The capacitor should be located

near the LM2575 using short pc board traces. Standard alu-

minum electrolytics are usually adequate, but low ESR types

are recommended for low output ripple voltage and good sta-

bility. The ESR of a capacitor depends on many factors, some

which are: the value, the voltage rating, physical size and the

type of construction. In general, low value or low voltage (less

than 12V) electrolytic capacitors usually have higher ESR

numbers.

The amount of output ripple voltage is primarily a function of

the ESR (Equivalent Series Resistance) of the output capac-

itor and the amplitude of the inductor ripple current (ΔI

See the section on inductor ripple current in Application Hints.

The lower capacitor values (220 μF–680 μF) will allow typi-

cally 50 mV to 150 mV of output ripple voltage, while larger-

value capacitors will reduce the ripple to approximately 20 mV

to 50 mV.

To further reduce the output ripple voltage, several standard

electrolytic capacitors may be paralleled, or a higher-grade

capacitor may be used. Such capacitors are often called

“high-frequency,” “low-inductance,” or “low-ESR.” These will

reduce the output ripple to 10 mV or 20 mV. However, when

operating in the continuous mode, reducing the ESR below

0.05Ω can cause instability in the regulator.

Tantalum capacitors can have a very low ESR, and should be

carefully evaluated if it is the only output capacitor. Because

of their good low temperature characteristics, a tantalum can

Output Ripple Voltage = (ΔI

IND

) (ESR of C

OUT

)

IND

).