HDSP-2533 Avago Technologies US Inc., HDSP-2533 Datasheet - Page 12

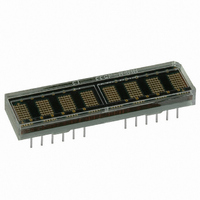

HDSP-2533

Manufacturer Part Number

HDSP-2533

Description

LED DISPLAY 5X7 8CHAR 5MM GREEN

Manufacturer

Avago Technologies US Inc.

Series

HDSP-253xr

Datasheet

1.HDSP-2533.pdf

(15 pages)

Specifications of HDSP-2533

Display Type

Alphanumeric

Common Pin

*

Package / Case

28-DIP

Color

Green

Size / Dimension

1.69" x .45" (42.9mm x 11.4mm)

Number Of Digits/alpha

8

Digit/alpha Size

0.20" (5mm)

Number Of Digits

8

Character Size

2.54 mm x 4.57 mm

Illumination Color

Green

Wavelength

574 nm

Operating Voltage

5 V

Operating Current

370 mA

Maximum Operating Temperature

+ 85 C

Minimum Operating Temperature

- 40 C

Luminous Intensity

7.5 ucd

Viewing Area (w X H)

40.06 mm x 4.57 mm

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

516-1169-5

Self Test Function (Bits 5, 6)

Bit 6 of the Control Word Register is used to initiate the self

test function. Results of the internal self test are stored in

bit 5 of the Control Word. Bit 5 is a read only bit where bit

5 = “1” indicates a passed self test and bit 5 = “0” indicates

a failed self test.

Setting bit 6 to a logic 1 will start the self test function.

The built-in self test function of the IC consists of two

internal routines which exercises major portions of the

IC and illuminates all of the LEDs. The first routine cycles

the ASCII decoder ROM through all states and performs a

checksum on the output. If the checksum agrees with the

correct value, bit 5 is set to “ 1. ” The second routine provides

a visual test of the LEDs using the drive circuitry. This is ac-

complished by writing checkered and inverse checkered

patterns to the display. Each pattern is displayed for

approximately 2 seconds.

During the self test function the display must not be

accessed. The time needed to execute the self test

function is calculated by multiplying the clock period by

262,144. For example, assume a clock frequency of 58 KHz,

then the time to execute the self test function frequency is

equal to (262,144/58,000) = 4.5 second duration.

At the end of the self test function, the Character RAM

is loaded with blanks, the Control Word Register is set to

zeros except for bit 5, and the Flash RAM is cleared and the

UDC Address Register is set to all ones.

Clear Function (Bit 7)

Bit 7 of the Control Word will clear the Character RAM

and the Flash RAM. Setting bit 7 to a “1” will start the

clear function. Three clock cycles (110 ms min. using the

internal refresh clock) are required to complete the clear

function. The display must not be accessed while the

display is being cleared. When the clear function has been

completed, bit 7 will be reset to a “0. ” The ASCII character

code for a space (20H) will be loaded into the Character

RAM to blank the display and the Flash RAM will be loaded

with “1”s. The UDC RAM, UDC Address Register and the re-

mainder of the Control Word are unaffected.

12

Display Reset

Figure 7 shows the logic levels needed to reset the display.

The display should be reset on Power-up. The external

Reset clears the Character RAM, Flash RAM, Control Word

and resets the internal counters. After the rising edge of

the Reset signal, three clock cycles (110 ms min. using the

internal refresh clock) are required to complete the reset

sequence. The display must not be accessed while the

display is being reset. The ASCII Character code for a space

(20H) will be loaded into the Character RAM to blank

the display. The Flash RAM and Control Word Register

are loaded with all “0”s. The UDC RAM and UDC Address

Register are unaffected. All displays which operate with

the same clock source must be simultaneously reset to

synchronize the Flashing and Blinking functions.

Mechanical Considerations

The HDSP-253X is assembled by die attaching and wire

bonding 280 LED chips and a CMOS IC to a thermally con-

ductive printed circuit board. A polycarbonate lens placed

over the pcb creates an air gap over the LED wire bonds. A

backfill epoxy seals the display package.

Figure 8 shows the proper method to insert the display

by hand. To prevent damage to the LED wire bonds, apply

pressure uniformly with fingers located at both ends of

the part. Using a tool, shown in Figure 9, such as a screw-

driver or pliers to push the display into the printed circuit

board or socket may damage the LED wire bonds. The

force exerted by a screwdriver is sufficient to push the lens

into the LED wire bonds. The bent wire bonds cause shorts

or opens that result in catastrophic failure of the LEDs.

Note:

If RST, CE, and WR are low, unkown data may be written into the display.

Figure 7. Logic levels to reset the display.

RST

0 = LOGIC 0; 1 = LOGIC 1; X = DO NOT CARE

0

CE

1

WR

X

RD

X

FL

X

A

4

X

-A

0

D

7

X

-D

0