HDSP-2111 Avago Technologies US Inc., HDSP-2111 Datasheet - Page 15

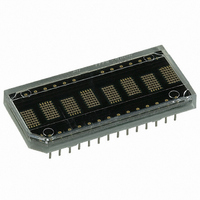

HDSP-2111

Manufacturer Part Number

HDSP-2111

Description

LED DISPLAY 5X7 8CHAR 5MM YLW

Manufacturer

Avago Technologies US Inc.

Series

HDSP-211xr

Datasheet

1.HDSP-2113.pdf

(16 pages)

Specifications of HDSP-2111

Display Type

Alphanumeric

Package / Case

28-DIP

Color

Yellow

Size / Dimension

1.68" L x 0.77" W x 0.21" H (42.59mm x 19.58mm x 5.31mm)

Number Of Digits/alpha

8

Common Pin

*

Digit/alpha Size

0.20" (5mm)

Number Of Digits

8

Character Size

5 mm x 7 mm

Illumination Color

Yellow

Wavelength

583 nm

Operating Voltage

4.5 V to 5.5 V

Maximum Operating Temperature

+ 85 C

Minimum Operating Temperature

- 45 C

Luminous Intensity

7.5 mcd

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

516-1162-5

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

HDSP-2111

Manufacturer:

AVAGO

Quantity:

201

Part Number:

HDSP-2111

Manufacturer:

AGILENT

Quantity:

20 000

Thermal Considerations

The HDSP-210X/-211X/-212X/250X have been designed

to provide a low ther mal resistance path for the CMOS

IC to the 26 package pins. Heat is typically conducted

through the traces of the printed circuit board to free

air. For most applications no addi tional heatsinking is

required.

Measurements were made on a 32 character display

string to determine the thermal resis tance of the display

assembly. Several display boards were con structed using

0.062 in. thick printed circuit material, and one ounce

copper 0.020 in. traces. Some of the device pins were

connected to a heatsink formed by etching a copper

area on the printed circuit board surround ing the display.

A maximally metallized printed circuit board was also

evaluated. The junc tion tem per ature was measured for

displays soldered directly to these PC boards, displays

installed in sockets, and finally displays installed in

sockets with a filter over the display to restrict air flow.

The results of these ther mal resistance measure ments,

Rq

Rq

Ground Connections

Two ground pins are provided to keep the internal IC

logic ground clean. The designer can, when necessary,

route the ana log ground for the LED drivers separately

from the logic ground until an appropriate ground

plane is available. On long inter con nec tions between

the display and the host system, the designer can keep

voltage drops on the analog ground from affect ing the

display logic levels by isolating the two grounds.

The logic ground should be connected to the same

ground poten tial as the logic interface cir cuitry.

The analog ground and the logic ground should be

connected at a common ground which can withstand

the cur rent introduced by the switch ing LED drivers.

When separate ground connec tions are used, the analog

ground can vary from -0.3 V to +0.3 V with re spect to the

logic ground. Volt age below -0.3 V can cause all dots to

be on. Voltage above +0.3 V can cause dimming and dot

mismatch.

Table 3. Thermal Resistance, T

of Heatsinking Material

Heatsinking

Metal

per Device

sq. in.

0

1

3

Max. Metal

4 Board Avg

15

J-A

J-C

.

are shown in Table 3 and include the effects of

W/Sockets

W/O Filter

(Avg.)

31

31

30

29

30

JA

, Using Various Amounts

W/O Sockets

W/O Filter

(Avg.)

30

28

26

25

27

W/Sockets

W/Filter

(Avg.)

35

33

33

32

33

Soldering and Post Solder

Cleaning Instructions for the

HDSP-210X/-211X/-250X

The HDSP-210X/-211X/-250X may be hand soldered or

wave soldered with SN63 solder. When hand soldering,

it is recom mended that an elec tronic ally tempera ture

con trolled and securely grounded soldering iron be used.

For best results, the iron tip temperature should be set at

315°C (600°F). For wave solder ing, a rosin-based RMA flux

can be used. The solder wave tem per a ture should be set

at 245°C ± 5°C (473°F ± 9°F), and the dwell in the wave

should be set between 1

soldering. The preheat tempera ture should not exceed

105°C (221°F) as measured on the solder side of the PC

board.

For addi tional information on solder ing and post solder

clean ing, see Application Note 1027, Soldering LED Com-

ponents.

Contrast Enhancement

The objective of contrast enhance ment is to provide

good readability in a variety of ambient lighting condi-

tions. For informa tion on contrast enhancement see

Appli ca tion Note 1015, Contrast Enhance ment Techniques

for LED Displays.

Units

°C/W

°C/W

°C/W

°C/W

°C/W

1

/

2

to 3 seconds for optimum