HLMP-D401 Avago Technologies US Inc., HLMP-D401 Datasheet

HLMP-D401

Specifications of HLMP-D401

Available stocks

Related parts for HLMP-D401

HLMP-D401 Summary of contents

Page 1

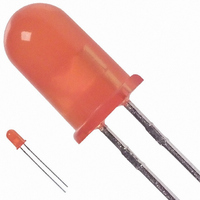

... HLMP-3301, HLMP-3401, HLMP-3507, HLMP-3762, HLMP-3862, HLMP-3962, HLMP-D401 3 T mm) Diffused LED Lamps 4 Data Sheet Description 3 This family of T-1 / tinted, diffused LED lamps is 4 widely used in general purpose indicator applications. Diffusants, tints, and optical design are balanced to yield superior light output and wide viewing angles. Several intensity choices are available in each color for increased design flexibility ...

Page 2

... Part Numbering System HLMP - Package Dimensions 2 Mechanical Option 00: Bulk 01: Tape & Reel, Crimped Leads 02: Tape & Reel, Straight Leads B1: Right Angle Housing, Uneven Leads B2: Right Angle Housing, Even Leads DD: Ammo Pack R4: Tape & Reel, Counter Clockwise Color Bin Options 0: Full Color Bin Distribution B: Color Bins 2 & ...

Page 3

Optical/Electrical Characteristics at T Symbol Parameter Included Angle 2 Between Half Luminous Intensity Points l Peak Wavelength PEAK Dl Spectral Line Halfwidth 1/2 l Dominant Wavelength d t Speed of Response s C Capacitance Rq Thermal Resistance ...

Page 4

Absolute Maximum Ratings 25°C A Parameter Peak Forward Current [1] Average Forward Current [2] DC Current [3] Power Dissipation Reverse Voltage (I = 100 µA) R Transient Forward Current [4] (10 µsec Pulse) LED Junction Temperature Operating ...

Page 5

T-1 / High Efficiency Red, Orange Diffused Lamps 4 Figure 2. Forward current vs. forward voltage characteristics Figure 5. Maximum tolerable peak current vs. pulse duration. (I MAX as per MAX ratings Figure 3. Relative luminous intensity ...

Page 6

T-1 / Yellow Diffused Lamps 4 Figure 7. Forward current vs. forward voltage characteristics Figure 10. Maximum tolerable peak current vs. pulse duration. (I MAX as per MAX ratings Figure 8. Relative luminous intensity vs. forward current ...

Page 7

T-1 / Green/Emerald Green Diffused Lamps 4 Figure 12. Forward current vs. forward voltage characteristics Figure 15. Maximum tolerable peak current vs. pulse duration. (I MAX as per MAX ratings Figure 13. Relative luminous intensity vs. DC ...

Page 8

Intensity Bin Limits Color Bin Red/Orange Yellow N ...

Page 9

Intensity Bin Limits, continued Color Bin Green Maximum tolerance for each bin limit is ±18%. Color Categories Color Category # ...

Page 10

Mechanical Option Matrix Mechanical Option Code Definition 00 Bulk Packaging, minimum increment 500 pcs/bag 01 Tape & Reel, crimped leads, minimum increment 1300 pcs/bag 02 Tape & Reel, straight leads, minimum increment 1300 pcs/bag B1 Right Angle Housing, uneven leads, ...

Page 11

Precautions Lead Forming • The leads of an LED lamp may be preformed or cut to length prior to insertion and soldering into PC board. • If lead forming is required before soldering, care must be taken to avoid any ...