RMPA5255 Fairchild Semiconductor, RMPA5255 Datasheet - Page 6

RMPA5255

Manufacturer Part Number

RMPA5255

Description

IC PWR AMP MOD 4.9-5.9GHZ 10-LCC

Manufacturer

Fairchild Semiconductor

Type

Power Amplifierr

Datasheet

1.RMPA5255.pdf

(7 pages)

Specifications of RMPA5255

Current - Supply

230mA

Frequency

4.9GHz ~ 5.9GHz

Gain

34dB

P1db

26dBm

Package / Case

11-LCC

Rf Type

WLL, WLAN

Voltage - Supply

3V ~ 3.6V

Number Of Channels

1

Frequency (max)

5.9GHz

Output Power

26dBm

Power Supply Requirement

Single

Single Supply Voltage (min)

3V

Single Supply Voltage (typ)

3.3V

Single Supply Voltage (max)

3.6V

Package Type

PLCC

Dual Supply Voltage (min)

Not RequiredV

Dual Supply Voltage (typ)

Not RequiredV

Dual Supply Voltage (max)

Not RequiredV

Supply Current

230mA

Pin Count

10

Mounting

Surface Mount

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Noise Figure

-

Test Frequency

-

Lead Free Status / Rohs Status

Compliant

Other names

RMPA5255TR

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

RMPA5255

Manufacturer:

AD

Quantity:

1 433

Part Number:

RMPA5255

Manufacturer:

FAIRCHILD/仙童

Quantity:

20 000

RMPA5255 Rev. E

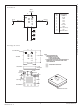

Recommended Solder Reflow Profile

Applications Information

CAUTION: THIS IS AN ESD SENSITIVE DEVICE.

Precautions to Avoid Permanent Device Damage:

• Cleanliness: Observe proper handling procedures to ensure

• Device Cleaning: Standard board cleaning techniques should

• Static Sensitivity: Follow ESD precautions to protect against

• General Handling: Handle the package on the top with a

• Device Storage: Devices are supplied in heat-sealed,

Device Usage:

Fairchild recommends the following procedures prior to

assembly.

• Assemble the devices within 7 days of removal from the dry

• During the 7-day period, the devices must be stored in an

• If the 7-day period or the environmental conditions have been

clean devices and PCBs. Devices should remain in their

original packaging until component placement to ensure no

contamination or damage to RF, DC and ground contact

areas.

not present device problems provided that the boards are

properly dried to remove solvents or water residues.

ESD damage:

– A properly grounded static-dissipative surface on which to

– Static-dissipative floor or mat.

– A properly grounded conductive wrist strap for each person

vacuum collet or along the edges with a sharp pair of bent

tweezers. Avoiding damaging the RF, DC, and ground

contacts on the package bottom. Do not apply excessive

pressure to the top of the lid.

moisture-barrier bags. In this condition, devices are protected

and require no special storage conditions. Once the sealed

bag has been opened, devices should be stored in a dry

nitrogen environment.

pack.

environment of less than 60% relative humidity and a

maximum temperature of 30°C

exceeded, then the dry-bake procedure, at 125°C for 24 hours

minimum, must be performed.

place devices.

to wear while handling devices.

100

260

217

200

150

50

25

Ramp-Up R ate

3 °C/sec max

Time 25 °C/sec t o peak tem p

6 mi nutes max

Preheat, 150 to 200 °C

60 - 180 sec

Ramp-Up R ate

3 °C/sec max

6

Time (Sec)

Solder Materials & Temperature Profile:

Reflow soldering is the preferred method of SMT attachment.

Hand soldering is not recommended.

Reflow Profile

• Ramp-up: During this stage the solvents are evaporated from

• Pre-heat/soak: The soak temperature stage serves two

• Reflow Zone: If the temperature is too high, then devices may

• Cooling Zone: Steep thermal gradients may give rise to

Solder Joint Characteristics:

Proper operation of this device depends on a reliable void-free

attachment of the heat sink to the PWB. The solder joint should

be 95% void-free and be a consistent thickness.

Rework Considerations:

Rework of a device attached to a board is limited to reflow of the

solder with a heat gun. The device should be subjected to no

more than 15°C above the solder melting temperature for no

more than 5 seconds. No more than 2 rework operations should

be performed.

the solder paste. Care should be taken to prevent rapid

oxidation (or paste slump) and solder bursts caused by violent

solvent out-gassing. A maximum heating rate is 3°C/sec.

purposes; the flux is activated and the board and devices

achieve a uniform temperature. The recommended soak

condition is: 60-180 seconds at 150-200°C.

be damaged by mechanical stress due to thermal mismatch or

there may be problems due to excessive solder oxidation.

Excessive time at temperature can enhance the formation of

inter-metallic compounds at the lead/board interface and may

lead to early mechanical failure of the joint. Reflow must occur

prior to the flux being completely driven off. The duration of

peak reflow temperature should not exceed 20 seconds.

Soldering temperatures should be in the range 255–260°C,

with a maximum limit of 260°C.

excessive thermal shock. However, rapid cooling promotes a

finer grain structure and a more crack-resistant solder joint.

The illustration below indicates the recommended soldering

profile.

Ramp-Do wn Rate

6 °C/sec max

260 +0/-5 °C

Peak tem p

10 - 20 sec

li quidus temp

60 - 150 sec

Time above

www.fairchildsemi.com