CRD1600 Cirrus Logic Inc, CRD1600 Datasheet - Page 3

CRD1600

Manufacturer Part Number

CRD1600

Description

High-efficiency PFC + Fluorescent Lamp Driver Reference Design

Manufacturer

Cirrus Logic Inc

Datasheet

1.CRD1600.pdf

(12 pages)

Specifications of CRD1600

Silicon Manufacturer

Cirrus Logic

Application Sub Type

Power Factor Correction (PFC)

Kit Application Type

Power Management

Silicon Core Number

CS1600

Utilized Ic / Part

CS1600

Main Purpose

Lighting, Ballast Control

Secondary Attributes

Power Factor Corrected (PFC)

Embedded

No

Primary Attributes

Input 108 ~ 305 VAC

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

CRD1600-120W

1. INTRODUCTION

The CS1600 is a high-performance Variable Frequency Discontinuous Conduction Mode (VF-DCM), ac-

tive Power Factor Correction (PFC) controller, optimized to deliver the lowest PFC system cost for elec-

tronic ballast applications

The CS1600 uses a digital control algorithm that is optimized for high efficiency

.

and near unity power factor over a wide input voltage range (108-305 VAC).

The CS1600 uses an adaptive digital control algorithm. Both the ON time and the switching frequency are

varied on a cycle-by-cycle basis over the entire AC line to achieve close to unity power factor. The varia-

tion in switching frequency also provides a spread frequency spectrum, thus minimizing the conducted

EMI filtering requirements.

The feedback loop is closed through an integrated digital control system within the IC. Protection features

such as overvoltage, overcurrent, overpower, open circuit, overtemperature, and brownout help protect

the device during abnormal transient conditions. Details of these features are provided in the CS1600 data

sheet.

The CRD1600-120W board demonstrates the performance of the CS1600 over a wide input voltage

range. This board has been designed to generate 460V from the PFC stage, which is then processed by

the resonant driver, to power up to two T5 lamps connected in series, for a total output of 108W.

Extreme caution needs to be exercised while handling this board. This board should be energized by

trained professionals only.

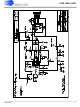

Terminal block J1 is used to connect the AC line. The lamp is connected to terminal J2 as shown in the

schematic.

J1

J2

AC Line

Output

Input

Terminals

Figure 1. Board Connections

WARNING

High Voltage Hazard

ONLY QUALIFIED PERSONNEL SHOULD HANDLE THE CRD1600-120W.

CAUTION:

Heatsinking is required for Q1.

The end product should use tar pitch or an equivalent compound for this purpose.

For lab evaluation purposes, a fan is recommended to provide adequate cooling.

DS904RD4

3