HV9910LG-G Supertex, HV9910LG-G Datasheet - Page 4

HV9910LG-G

Manufacturer Part Number

HV9910LG-G

Description

LED Drivers Universal Hi Bright

Manufacturer

Supertex

Specifications of HV9910LG-G

Operating Supply Voltage

8 V to 450 V

Maximum Power Dissipation

630 mW

Maximum Operating Temperature

+ 85 C

Mounting Style

SMD/SMT

Package / Case

SOIC-8

Minimum Operating Temperature

- 40 C

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Application Information

AC/DC Off-Line Applications

The HV9910 is a low-cost off-line buck or boost converter

control IC specifi cally designed for driving multi-LED stings

or arrays. It can be operated from either universal AC line

or any DC voltage between 8-450V. Optionally, a passive

power factor correction circuit can be used in order to pass

the AC harmonic limits set by EN 61000-3-2 Class C for

lighting equipment having input power less than 25W. The

HV9910 can drive up to hundreds of High-Brightness (HB)

LEDs or multiple strings of HB LEDs. The LED arrays can

be confi gured as a series or series/parallel connection. The

HV9910 regulates constant current that ensures controlled

brightness and spectrum of the LEDs, and extends their

lifetime. The HV9910 features an enable pin (PWM_D) that

allows PWM control of brightness.

The HV9910 can also control brightness of LEDs by

programming continuous output current of the LED driver

(so-called linear dimming) when a control voltage is applied

to the LD pin.

The HV9910 is offered in a standard 8-pin SOIC package. It

is also available in a high voltage rated SO-16 package for

applications that require V

The HV9910 includes an internal high-voltage linear regulator

that powers all internal circuits and can also serve as a bias

supply for low voltage external circuitry.

LED Driver Operation

The HV9910 can control all basic types of converters, isolated

or non-isolated, operating in continuous or discontinuous

conduction mode. When the gate signal enhances the external

power MOSFET, the LED driver stores the input energy in an

inductor or in the primary inductance of a transformer and,

depending on the converter type, may partially deliver the

energy directly to LEDs The energy stored in the magnetic

component is further delivered to the output during the off-

cycle of the power MOSFET producing current through the

string of LEDs (Flyback mode of operation).

When the voltage at the V

the gate drive is enabled. The output current is controlled

by means of limiting peak current in the external power

MOSFET. A current sense resistor is connected in series

with the source terminal of the MOSFET. The voltage from

the sense resistor is applied to the CS pin of the HV9910.

When the voltage at CS pin exceeds a peak current sense

voltage threshold, the gate drive signal terminates, and the

power MOSFET turns off. The threshold is internally set

to 250mV, or it can be programmed externally by applying

DD

IN

pin exceeds the UVLO threshold

greater than 250V.

4

voltage to the LD pin. When soft start is required, a capacitor

can be connected to the LD pin to allow this voltage to ramp

at a desired rate, therefore, assuring that output current of

the LED ramps gradually.

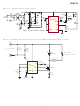

Optionally, a simple passive power factor correction circuit,

consisting of 3 diodes and 2 capacitors, can be added as

shown in the typical application circuit diagram of Figure 1.

Supply Current

A current of 1mA is needed to start the HV9910. As shown

in the block diagram on page 3, this current is internally

generated in the HV9910 without using bulky startup resistors

typically required in the offl ine applications. Moreover, in

many applications the HV9910 can be continuously powered

using its internal linear regulator that provides a regulated

voltage of 7.5V for all internal circuits.

Setting Light Output

When the buck converter topology of Figure 2 is selected,

the peak CS voltage is a good representation of the average

current in the LED. However, there is a certain error

associated with this current sensing method that needs to

be accounted for. This error is introduced by the difference

between the peak and the average current in the inductor.

For example if the peak-to-peak ripple current in the inductor

is 150mA, to get a 500mA LED current, the sense resistor

should be 250mV/(500mA+ 0.5*150mA) = 0.43Ω.

Dimming

Dimming can be accomplished in two ways, separately or

combined, depending on the application. Light output of the

LED can be controlled either by linear change of its current,

or by switching the current on and off while maintaining it

constant. The second dimming method (so-called PWM

dimming) controls the LED brightness by varying the duty

ratio of the output current.

The linear dimming can be implemented by applying a

control voltage from 0 to 250mV to the LD pin. This control

voltage overrides the internally set 250mV threshold level

of the CS pin and programs the output current accordingly.

For example, a potentiometer connected between V

ground can program the control voltage at the CS pin.

Applying a control voltage higher than 250mV will not change

the output current setting. When higher current is desired,

select a smaller sense resistor.

The PWM dimming scheme can be implemented by applying

an external PWM signal to the PWM_D pin. The PWM signal

HV9910

DD

and