HV9910LG-G Supertex, HV9910LG-G Datasheet - Page 5

HV9910LG-G

Manufacturer Part Number

HV9910LG-G

Description

LED Drivers Universal Hi Bright

Manufacturer

Supertex

Specifications of HV9910LG-G

Operating Supply Voltage

8 V to 450 V

Maximum Power Dissipation

630 mW

Maximum Operating Temperature

+ 85 C

Mounting Style

SMD/SMT

Package / Case

SOIC-8

Minimum Operating Temperature

- 40 C

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

can be generated by a microcontroller or a pulse generator

with a duty cycle proportional to the amount of desired

light output. This signal enables and disables the converter

modulating the LED current in the PWM fashion. In this

mode, LED current can be in one of the two states: zero or

the nominal current set by the current sense resistor. It is not

possible to use this method to achieve average brightness

levels higher than the one set by the current sense threshold

level of the HV9910. By using the PWM control method of

the HV9910, the light output can be adjusted between zero

and 100%. The accuracy of the PWM dimming method is

limited only by the minimum gate pulse width, which is a

fraction of a percent of the low frequency duty cycle.

Some of the typical waveforms illustrating the PWM dimming

method used with the application circuit on page 7 are given

below. CH

PWM signal to pin PWM_D and CH

LED string.

1

33% PWM Ratio at 500Hz Dimming

95% PWM Ratio at 500Hz Dimming

shows the MOSFET Drain voltage, CH

4

is the current in the

2

is the

5

Programming Operating Frequency

The operating frequency of the oscillator is programmed

between 25 and 300kHz using an external resistor connected

to the R

F

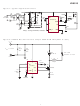

Power Factor Correction

When the input power to the LED driver does not exceed

25W, a simple passive power factor correction circuit can be

added to the HV9910 typical application circuit on page 7 in

order to pass the AC line harmonic limits of the EN61000-

3-2 standard for Class C equipment. The typical application

circuit diagram shows how this can be done without affecting

the rest of the circuit signifi cantly. A simple circuit consisting

of 3 diodes and 2 capacitors is added across the rectifi ed AC

line input to improve the line current harmonic distortion and

to achieve a power factor greater than 0.85.

Inductor Design

Referring to the typical application circuit on page 7 the

value can be calculated from the desired peak-to-peak LED

ripple current in the inductor. Typically, such ripple current

is selected to be 30% of the nominal LED current. In the

example given here, the nominal current I

The next step is determining the total voltage drop across

the LED string. For example, when the string consists of 10

High-Brightness LEDs and each diode has a forward voltage

drop of 3.0V at its nominal current; the total LED voltage

V

OSC

LEDS

= 25000/(R

is 30V.

T

pin:

0.4% PWM Ratio at 500Hz Dimming

T

[kΩ] + 22) [kHz]

LED

is 350mA.

HV9910