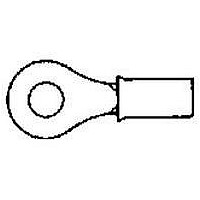

320576 TE Connectivity, 320576 Datasheet

320576

Specifications of 320576

Available stocks

Related parts for 320576

320576 Summary of contents

Page 1

NOTE 1. INTRODUCTION This specification covers the requirements for application of PIDG terminals, splices, and end caps in various operating environments. Each consists of a precision–formed metal wire barrel and a copper sleeve encased in insulating material made of nylon, ...

Page 2

Butt Splice Opaque Insulation Transparent Insulation Window 2. REFERENCE MATERIAL 2.1. Revision Summary Revisions to this application specification include: S Updated document to corporate requirements S Changed text in Section 1, INTRODUCTION and Paragraphs 3.4, 3.8, S Switched Paragraphs 3.5.C ...

Page 3

TETRA–CRIMP* Hand Crimping Tool 59824–1 408–3295 Preparing (Reel–Wrap) Reel of Contacts for Applicator Tooling 408–4099 Pneumatic TETRA–CRIMP Adapter 679305–1 408–4105 626 Straight Action Crimper 217200–[ ] 408–7424 Checking Terminal Crimp Height or Gaging Die Closure 408–8044 Miniature Quick–Change Applicator ...

Page 4

Note: WIRE TERMINAL, SPLICE, OR END CAP OR END CAP SIZE (AWG) DIAMETER RANGE INSULATION COLOR Contact PRODUCT INFORMATION at the number on page ...

Page 5

Wire Placement The stripped wire must be inserted into the wire barrel until the wire insulation is against the wire barrel but not inside it. The wire insulation must be inside the metal sleeve. A gap between the wire ...

Page 6

Yellow/Black 26-24 Yellow 26-22 Yellow 24 Yellow/Blue White 24 20 24-20 Natural/White 22 Red/Green Red 22- Natural/Red 20 Red/Red 18 Red/White 16 Blue/Blue Blue 16 14 16-14 Natural/Blue 14 Blue/Green D Yellow/Black 16-14 12 Yellow/Yellow Yellow 12-10 ...

Page 7

Terminal Shown Note: Dot Code (1 Dot Shown) is Well Formed and Corresponds With Crimping Chamber of Tooling Used Wire Insulation Inside Metal Sleeve But Not Inside Wire Barrel No Flash in This Area Detail A Splice Wire Flush to ...

Page 8

Using an unstripped wire, make a test crimp. 2. Hold the terminal, splice, or end cap in one hand. Use the side of one finger on the other hand at approximately 76 [3] to push the wire up 90 ...

Page 9

Cross-Section of Insulation Crimp At Wire End of Terminals, Splice, or End Cap (Sketches represent the uppermost wire insulation range of the Terminals, Splice, or End Cap. Thinner wire insulation may appear slightly different, but will perform the same.) Refer ...

Page 10

Most, but not all, PIDG terminals, splices, and end caps meet the requirements of the following agencies: To ascertain whether a terminal, splice, or end cap (identified by part number) meets the requirements of the following agencies, contact PRODUCT INFORMATION ...

Page 11

HAND TOOL WIRE SIZE WIRE SIZE TETRA-CRIMP (AWG DAHT T-HD HT Hand Tool For use with terminals having an insulation thickness range of 0.51–0.84 [.020–.033]. D For use with heavy duty terminals having an ...

Page 12

Tape-Mounted Terminal, Splice, or End Cap Die Assemblies and Applicators For use with terminals having an insulation thickness range of 0.51–0.84 [.020–.033]. D For use with ...

Page 13

VISUAL AID Figure 11 shows a typical application of PIDG terminals, splices, and end caps. This illustration should be used by production personnel to ensure a correctly applied terminal, splice, or end cap. Applications which DO NOT appear correct ...

Page 14

Small Amount of Space Between Wire Conductor(s) and Wire Barrel Front Bellmouth on Top of Insulation No Space Between Wire Conductor(s) and Wire Barrel No Bellmouth on Top of Insulation Too Much Space Between Wire Conductor(s) and Wire Barrel Front ...