2-406372-6 TE Connectivity, 2-406372-6 Datasheet

2-406372-6

Specifications of 2-406372-6

Related parts for 2-406372-6

2-406372-6 Summary of contents

Page 1

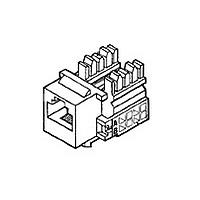

... Category 5 110 panel mount modular jacks. These assemblies are designed for panel mounting and provide insulation displacing 110 punchdown blocks for terminating both shielded and unshielded twisted pair conductors to the jacks. 110 blocks are designed to terminate AWG solid or stranded conductors having a maximum overall diameter of .050. Jacks are available in fully shielded, unshielded and grounded styles ...

Page 2

... Emission levels can be affected by many variables such as cable type, cable length, grounding method and test setup. Contribution of a shielded connector to overall shielding will vary with each application. Typically, a shielded modular plug/jack interface may be expected to improve shielding effectiveness approximately compared to an unshielded interface. ! Frequency range: • ...

Page 3

... Hz traversed in 1 minute at .06 inches total excursion. 15 minutes in each of 3 mutually perpendicular planes. TE Spec 109-50. Apply axial load of 20 pounds to plug housing at rate of .5 inch per minute with plug mated in jack and latch engaged. TE Spec 109-26-1. Subject mated jack and plug assembly to 50 G's half-sine shock pulses of 11 milliseconds duration ...

Page 4

... Housing panel retention. Thermal shock. Humidity-temperature cycling. Mixed flowing gas. Temperature life. Shall meet visual requirements, show no physical damage and shall meet requirements of NOTE additional tests specified in Test Sequence in Figure 2. Rev B Requirement 20 pounds minimum. ENVIRONMENTAL Insulation resistance. Termination resistance, dry circuit final. ...

Page 5

... Sheets and shall be selected at random from current production. All test groups shall consist of 10, 110 panel mount jacks and 10 terminated plugs. B. Test sequence. Qualification inspection shall be verified by testing samples as specified in Figure 2. 4.2. Requalification Testing If changes significantly affecting form, fit or function are made to product or manufacturing process, product assurance shall coordinate requalification testing consisting of all or part of original testing sequence as determined by development/product, quality and reliability engineering ...

Page 6

... Printed circuit board trace length varies with each jack position, therefore, significant variations in termination resistance readings can be expected within each jack assembly. (b) Millivolt drop (resistance) due to 6 inch and 2 inch wire lengths shall be subtracted from all readings. Rev B ...