XLT28SO-1 Microchip Technology, XLT28SO-1 Datasheet - Page 17

XLT28SO-1

Manufacturer Part Number

XLT28SO-1

Description

SOCKET TRANSITION 28SOIC 300MIL

Manufacturer

Microchip Technology

Specifications of XLT28SO-1

Module/board Type

*

Svhc

No SVHC (15-Dec-2010)

Lead Free Status / RoHS Status

Not applicable / Not applicable

For Use With/related Products

MPLAB™ICE

For Use With

AC162067 - HEADER INTRFC MPLAB ICD2 40/28PDAF18-4 - DEVICE ADAPTER FOR ICE4000DAF30-4 - DEVICE ATP FOR ICE4000DVA18XP280 - DEVICE ADAPTER 18F2220 PDIP 28LDDVA16XP280 - ADAPTER DEVICE FOR MPLAB-ICEICE2000 - EMULATOR MPLAB-ICE 2000 POD

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Not applicable / Not applicable

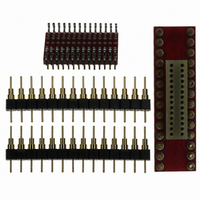

QFP TRANSITION SOCKET

QFP (MQFP, TQFP, PQFP) transition sockets and

associated hardware are shown below.

FIGURE 4: QFP TRANSITION SOCKET

The QFP transition socket is required for use along with

the QFP device adapter. The device adapter is

equipped with four socket strips that interface with the

transition socket.

There are two parts to the QFP transition socket:

1.

2.

Microchip offers the following QFP transition sockets:

• XLT44PT3: One 44-lead QFP adapter socket and

• XLT64PT5: One 64-lead QFP adapter socket and

• XLT80PT2: One 80-lead QFP adapter socket and

• XLT80PT3: One 80-lead QFP adapter socket and

See the drawings in this section for layout dimensions

and clearances for tall components.

2010 Microchip Technology Inc.

Note:

one 44-lead QFP header (0.8 mm)

one 64-lead QFP header (0.5 mm)

one 80-lead QFP header (0.65 mm)

one 80-lead QFP header (0.5 mm)

Adapter socket that connects to the QFP device

adapter

QFP header that gets soldered down to the

target application

To avoid solder bridging, do not place vias

within 0.025-inch of the QFP footprint.

Also, any vias near the QFP should be

directly on the centerline of the pad.

QFP Transition Socket

QFP Device Adapter

Cable to Processor Module

Target/Application Board

Transition Socket Specification

QFP TRANSITION SOCKET

SOLDERING TIPS

• Use controlled soldering iron tip temperatures

• If possible, use a PACE mini wave soldering iron

• Plan to solder one (1 of 4) side first, then the

• Soldering iron tip movement should be in the

• Use generous amounts of soldering flux to aid in

between 300C and 325C (570F to 615F)

tip or an equivalent tip design.

opposite side, then the remaining two sides.

direction of the leads (backward and forward), not

across the leads; dragging the tip across the

leads may cause lead damage.

the solder flow action.

DS51194S-page 17