NCR100KR-73-150R Yageo, NCR100KR-73-150R Datasheet - Page 6

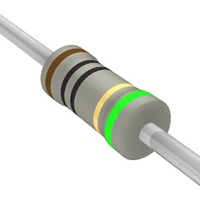

NCR100KR-73-150R

Manufacturer Part Number

NCR100KR-73-150R

Description

RES CARBON FILM 150 OHM 1W 10%

Manufacturer

Yageo

Series

NCRr

Datasheet

1.NCR-25KR-52-10R.pdf

(10 pages)

Specifications of NCR100KR-73-150R

Resistance (ohms)

150

Power (watts)

1W

Composition

Carbon Film

Features

Flame Proof, Non-Inductive

Temperature Coefficient

-500ppm/°C

Tolerance

±10%

Size / Dimension

0.177" Dia x 0.453" L (4.50mm x 11.50mm)

Lead Style

Through Hole

Package / Case

Axial

Resistance In Ohms

150

Case

Axial

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Height

-

(4) Insulation Resistance

(6) Resistance to Solvent

(7) Terminal Strength

(8) Pulse Overload

(10) Load Life Test

(3) Temperature Coefficient Test

(5) Solderability

(9) Load Life in Humidity

Test of resistors above room temperature 100°C ± 2°C ( Testing Temperature 115°C to 130°C ) at the

constant temperature silicon plate for over 5 minutes. Then measure the resistance value.

The Temperature Coefficient is calculated by the following equation and its value should be within the

range of requested.

Apply test terminal on lead and resistor body.

The test resistance should be high than 1,000M ohm.

Immerse the specimen into the solder pot at 260 ± 5 °C for 5 ± 0.5 seconds.

At least 95% solder coverage on the termination.

The specimen into the appropriate solvent of IPA condition of ultrasonic machine for 1 minutes.

The specimen is no deterioration of coatings and color code.

Direct Load – Resistors shall be held by one terminal and the load shall be gradually applied in the

direction of the longitudinal axis of the resistor unit the applied load reacheds 5 pounds。

The load shall be held for 10 seconds. The load of weight shall be ≧ 2.5 kg ( 24.5N ).

Apply 4 times of rated voltage to the specimen at the 1 second on and 25 seconds off cycle, subjected

to voltage application cycles specified in 10,000 time。

The change of the resistance value shall be within ± 1.0% + 0.05 Ω

Place the specimen in a test chamber at 40 ± 2 °C and 90 ~ 95 % relative humidity. Apply the rated

voltage to the specimen at the 1.5 hours on and 0.5 hour off cycle. The total length of test is 1,000 hours

The change of the resistance value shall be within ± 3 % + 0.05 Ω

Placed in the constant temperature chamber of 70 ± 3 °C the resistor shall be connected to the lead wire

at the point of 25mm. Length with each terminal, the resistors shall be arranged not much effected

mutually by the temperature of the resistors and the excessive ventilation shall not be performed, for 90

minutes on and 30 minutes off under this condition the rated D.C. voltage is applied continuously for

1000+48/-0 hours then left at no-load for 1hour, measured at this time the resistance value。

The change of the resistance value shall be within ± 3 % + 0.05 Ω.

There shall be no remarkable change in the appearance and the color code shall be legible after the test.

Re

sistor

R = Resistance value under the testing temperature

R

t

t

o

0

= Resistance value at the room temperature

= The testing temperature

= Room temperature

Temperatur

e

Coefficien

Page-6

t

=

R

R

−

R

0

0

×

t

−

1

t

0

×

10

6