75003-0210 Molex Inc, 75003-0210 Datasheet - Page 5

75003-0210

Manufacturer Part Number

75003-0210

Description

CONN PLUG 72POS 1.2MM VERT SMD

Manufacturer

Molex Inc

Series

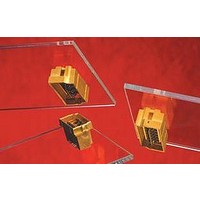

Plateau HS Mezz™ 75003r

Datasheets

1.75005-0306.pdf

(7 pages)

2.75005-0306.pdf

(9 pages)

3.75005-0306.pdf

(12 pages)

4.75003-0210.pdf

(8 pages)

Specifications of 75003-0210

Connector Type

Differential Pair Array, Male

Number Of Positions

72

Pitch

0.047" (1.20mm)

Number Of Rows

2

Mounting Type

Surface Mount

Features

Board Guide

Contact Finish

Gold

Contact Finish Thickness

30µin (0.76µm)

Mated Stacking Heights

15mm, 17mm, 25mm

Height Above Board

0.522" (13.25mm)

Pitch Spacing

1.2mm

No. Of Contacts

72

Gender

Plug

Contact Plating

Gold

No. Of Rows

2

Contact Termination

Surface Mount Vertical

Product Type

Receptacles

Mounting Style

Wire

Number Of Positions / Contacts

6

Housing Material

High Temperature Thermoplastic

Contact Material

High Performance Alloy (HPA)

Voltage Rating

30 V

Current Rating

1.5 A

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

075003-0210

075003-0210-E

0750030210

0750030210-E

75003-0210-E

750030210

750030210-E

WM17217

075003-0210-E

0750030210

0750030210-E

75003-0210-E

750030210

750030210-E

WM17217

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

75003-0210

Manufacturer:

Molex, LLC

Quantity:

12 000

REVISION:

DOCUMENT NUMBER:

B

PS-75005-001

5.4.2 Temperature Life: There shall be no change in contact resistance greater than 10mOhms

5.4.3 Temperature Life (preconditioning): There shall be no change in contact resistance greater

5.4.4 Cyclic Humidity: There shall be no change in contact resistance greater than 10mOhms

5.4.5 Thermal Disturbance: There shall be no change in contact resistance greater than 10mOhms

5.4.6 Mixed Flowing Gas: There shall be no change in contact resistance greater than 10mOhms

5.4.7 Thermal Cycling: There shall be no change in contact resistance greater than 10mOhms

5.4.8 Temperature Rise: Apply an increasing current and monitor temperature until a DT of

5.4.9 Plating Adhesion: Plating will show no flaking, peeling, or other adhesion failure after

ECR/ECN INFORMATION:

EC No:

DATE:

from initial when mated specimens are subjected to 85

17, Method A, Test Condition 4.

from initial when mated specimens are subjected to 24 cycles between 25

65

extremes. Test per EIA-364-31.

from initial when mated specimens are cycled between 15

Temperature ramp should be 2

from initial when mated and unmated specimens are subjected to environmental Class II for

7 days. Test per EIA-364-65, for unmated specimens use Option 2.

from initial when mated specimens are cycled between 15

of 2

cycle 500 times.

30

was achieved as follows: 96 hours steady state, 240 hours current cycling (45 minutes on,

15 minutes off, repeat), 96 Hours steady state. Upon completion of the test, if the

temperature is below the DT of 30

the rated current.

being exposed to the following environmental sequences and then being subjected to a cross

cut tape test. The test will be performed as follows: one exposure to IR or convection oven

reflow temperatures, 5 cycles between -55

and 20 cycles of 4-4-16 (4 hours at 75

+/- 2.5

Test adhesion per ASTM D 3359-78 Method B.

than 10mOhms from initial when mated specimens are subjected to 85

Test per EIA-364-17, Method A, Test Condition 4.

UCP2003-2204

2003 / 04 / 10

o

o

C at 50 RH, with a 0.5 hour ramp time between extremes and a 1.0 hour dwell time at

C over the ambient temperature is achieved. Test at the current at which a DT of 30

o

C per minute. With a dwell time of at least 5 minutes. Humidity is not controlled,

o

C and 47.5% RH +/- 2.5%, 16 hours at 25

PRODUCT SPECIFICATION

HIGH SPEED MEZZANINE

TITLE:

CREATED / REVISED BY:

Ken Stiles

BOARD TO BOARD CONNECTOR SYSTEM

PRODUCT SPECIFICATION FOR THE

o

C per minute minimum with 5 minute dwell minimum.

o

C, then the current at which the test was run becomes

HIGH SPEED MEZZANINE

o

C +/- 2.5

o

C and 85

o

C and 92.5% RH +/- 2.5%, 4 hours at 75

CHECKED BY:

o

Ken Stiles

C +/- 2.5

o

C with 30 minute dwell at extremes,

o

C for 1000 hours. Test per EIA-364-

TEMPLATE FILENAME: PRODUCT_SPEC[SIZE_A](V.1).DOC

o

o

C and 85

C and 85

o

C and 47.5% RH +/- 2.5%).

o

o

C for 10 cycles .

C at a minimum ramp

o

C for 250 hours.

Manny Banakis

APPROVED BY:

o

C at 80% RH and

SHEET No.

5

of

7

o

C

o

C