SFN4D-DC24V Panasonic, SFN4D-DC24V Datasheet - Page 6

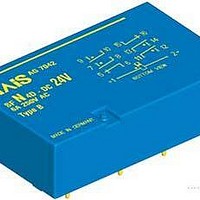

SFN4D-DC24V

Manufacturer Part Number

SFN4D-DC24V

Description

General Purpose / Industrial Relays Safety Relay 24VDC 4 Form A 2 Form B

Manufacturer

Panasonic

Datasheet

1.SFN4D-DC36V.pdf

(8 pages)

Specifications of SFN4D-DC24V

Contact Form

4 - NO, 2 - NC

Coil Voltage

24 VDC

Contact Termination

Through Hole

Mounting Style

PCB

Power Consumption

390 mW

Contact Material

Silver Tin Oxide

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

SFN4D

The SFN4D safety relay with welded contacts

6

- NC 5-6 welded.

- Coil energized.

- Armature nearly in

- NC 16-15 welded.

- Coil energized.

- Armature nearly in

- NO 12-11 welded.

- Coil deenergized.

- Armature nearly in

- NO 14-13 welded.

- Coil deenergized.

- Armature in nearly

- NO 7-8 welded.

- Coil deenergized.

- Armature in deenergized

- NO 9-10 welded.

- Coil deenergized.

- Armature in deenergized

deenergized position.

deenergized position.

energized position.

energized position.

position.

position.

Condition

Illustration of Relay State

5

6

5

6

5

6

5

6

5

6

5

6

8

8

7

8

8

8

8

7

7

7

7

7

10

10

10

10

10

10

9

9

9

9

9

9

12

11

12

11

12

11

12

11

12

11

12

11

Condition of Contacts

14

13

14

13

14

13

14

13

14

13

14

13

ds_61408_0000_en_sfn4d: 141106D

16

15

16

15

16

15

16

15

16

15

16

15

- All NO contacts are forcibly

- The NO contact gaps are

- For NC 16-15, the contact

- All NO contacts are forcibly

- The NO contact gaps are

- For NC 5-6, the contact

- All (both) NC contacts are

- The NC contact gaps are min.

- For all NO contacts, the

- All (both) NC contacts are

- The NC contact gaps are min.

- For all NO contacts, the

- NC 16-15 is closed!!

- All non-welded NO

- NC 5-6 forcibly guided to the

- NC 16-15 is closed!!

- All non-welded NO

- NC 5-6 forcibly guided to the

guided.

min. 0.5mm.

condition is not defined.

guided.

min. 0.5mm.

condition is not defined.

forcibly guided.

0.5mm.

contact condition is not

defined.

forcibly guided.

0.5mm.

contact condition is not

defined.

contacts show their max.

contact gap.

welded contact by sub card 1.

The contact gap is min.

0.5mm.

contacts show their max.

contact gap.

welded contact by sub card 2.

The contact gap is min.

0.5mm.