LM1876TF National Semiconductor, LM1876TF Datasheet - Page 16

LM1876TF

Manufacturer Part Number

LM1876TF

Description

Audio Power Amplifier IC

Manufacturer

National Semiconductor

Specifications of LM1876TF

No. Of Channels

2

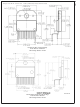

Amplifier Case Style

TO-220

No. Of Pins

15

Termination Type

Through Hole

Mounting Type

Through Hole

Peak Reflow Compatible (260 C)

No

Supply Voltage Max

22V

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

LM1876TF

Manufacturer:

NS/国半

Quantity:

20 000

Company:

Part Number:

LM1876TF/NOPB

Manufacturer:

RAYTHEON

Quantity:

334

www.national.com

Application Information

MUTE MODE

By placing a logic-high voltage on the mute pins, the signal

going into the amplifiers will be muted. If the mute pins are

left floating or connected to a logic-low voltage, the amplifi-

ers will be in a non-muted state. There are two mute pins,

one for each amplifier, so that one channel can be muted

without muting the other if the application requires such a

configuration. Refer to the Typical Performance Character-

istics section for curves concerning Mute Attenuation vs

Mute Pin Voltage.

STANDBY MODE

The standby mode of the LM1876 allows the user to drasti-

cally reduce power consumption when the amplifiers are

idle. By placing a logic-high voltage on the standby pins, the

amplifiers will go into Standby Mode. In this mode, the

current drawn from the V

µA total for both amplifiers. The current drawn from the V

supply is typically 4.2 mA. Clearly, there is a significant

reduction in idle power consumption when using the standby

mode. There are two Standby pins, so that one channel can

be put in standby mode without putting the other amplifier in

standby if the application requires such flexibility. Refer to

the Typical Performance Characteristics section for

curves showing Supply Current vs. Standby Pin Voltage for

both supplies.

UNDER-VOLTAGE PROTECTION

Upon system power-up, the under-voltage protection cir-

cuitry allows the power supplies and their corresponding

capacitors to come up close to their full values before turning

on the LM1876 such that no DC output spikes occur. Upon

turn-off, the output of the LM1876 is brought to ground

before the power supplies such that no transients occur at

power-down.

OVER-VOLTAGE PROTECTION

The LM1876 contains over-voltage protection circuitry that

limits the output current to approximately 3.5 Apk while also

providing voltage clamping, though not through internal

clamping diodes. The clamping effect is quite the same,

however, the output transistors are designed to work alter-

nately by sinking large current spikes.

SPiKe PROTECTION

The LM1876 is protected from instantaneous peak-

temperature stressing of the power transistor array. The Safe

Operating graph in the Typical Performance Characteris-

tics section shows the area of device operation where

SPiKe Protection Circuitry is not enabled. The waveform to

the right of the SOA graph exemplifies how the dynamic

protection will cause waveform distortion when enabled.

THERMAL PROTECTION

The LM1876 has a sophisticated thermal protection scheme

to prevent long-term thermal stress of the device. When the

temperature on the die reaches 165˚C, the LM1876 shuts

down. It starts operating again when the die temperature

drops to about 155˚C, but if the temperature again begins to

rise, shutdown will occur again at 165˚C. Therefore, the

device is allowed to heat up to a relatively high temperature

if the fault condition is temporary, but a sustained fault will

cause the device to cycle in a Schmitt Trigger fashion be-

tween the thermal shutdown temperature limits of 165˚C and

CC

supply is typically less than 10

EE

16

155˚C. This greatly reduces the stress imposed on the IC by

thermal cycling, which in turn improves its reliability under

sustained fault conditions.

Since the die temperature is directly dependent upon the

heat sink used, the heat sink should be chosen such that

thermal shutdown will not be reached during normal opera-

tion. Using the best heat sink possible within the cost and

space constraints of the system will improve the long-term

reliability of any power semiconductor device, as discussed

in the Determining the Correct Heat Sink Section.

DETERMlNlNG MAXIMUM POWER DISSIPATION

Power dissipation within the integrated circuit package is a

very important parameter requiring a thorough understand-

ing if optimum power output is to be obtained. An incorrect

maximum power dissipation calculation may result in inad-

equate heat sinking causing thermal shutdown and thus

limiting the output power.

Equation (1) exemplifies the theoretical maximum power

dissipation point of each amplifier where V

supply voltage.

Thus by knowing the total supply voltage and rated output

load, the maximum power dissipation point can be calcu-

lated. The package dissipation is twice the number which

results from equation (1) since there are two amplifiers in

each LM1876. Refer to the graphs of Power Dissipation

versus Output Power in the Typical Performance Charac-

teristics section which show the actual full range of power

dissipation not just the maximum theoretical point that re-

sults from equation (1).

DETERMINING THE CORRECT HEAT SINK

The choice of a heat sink for a high-power audio amplifier is

made entirely to keep the die temperature at a level such

that the thermal protection circuitry does not operate under

normal circumstances.

The thermal resistance from the die (junction) to the outside

air (ambient) is a combination of three thermal resistances,

θ

(junction to case), of the LM1876TF is 2˚C/W and the

LM1876T is 1˚C/W. Using Thermalloy Thermacote thermal

compound, the thermal resistance, θ

about 0.2˚C/W. Since convection heat flow (power dissipa-

tion) is analogous to current flow, thermal resistance is

analogous to electrical resistance, and temperature drops

are analogous to voltage drops, the power dissipation out of

the LM1876 is equal to the following:

where T

ture and θ

Once the maximum package power dissipation has been

calculated using equation (1), the maximum thermal resis-

tance, θ

be calculated. This calculation is made using equation (3)

which is derived by solving for θ

Again it must be noted that the value of θ

upon the system designer’s amplifier requirements. If the

ambient temperature that the audio amplifier is to be working

under is higher than 25˚C, then the thermal resistance for the

heat sink, given all other things are equal, will need to be

smaller.

JC

, θ

CS

θ

SA

SA

JMAX

, and θ

JA

, (heat sink to ambient) in ˚C/W for a heat sink can

= [(T

= θ

= 150˚C, T

JMAX

SA

P

JC

DMAX

. In addition, the thermal resistance, θ

P

+ θ

−T

DMAX

CS

AMB

= (T

AMB

+ θ

= V

)−P

JMAX

is the system ambient tempera-

SA

CC

DMAX

.

SA

−T

2/2π

AMB

(θ

in equation (2).

2

JC

R

CS

)/θ

L

+θ

JA

(case to sink), is

CS

SA

CC

)]/P

is dependent

is the total

DMAX

(1)

(2)

(3)

JC