LSM-0.75/16-D12-C Murata Power Solutions Inc, LSM-0.75/16-D12-C Datasheet - Page 11

LSM-0.75/16-D12-C

Manufacturer Part Number

LSM-0.75/16-D12-C

Description

DC/DC SM 16A 12-0.75V Non-Iso

Manufacturer

Murata Power Solutions Inc

Series

LSMr

Datasheet

1.LSM-0.7516-D12-C.pdf

(12 pages)

Specifications of LSM-0.75/16-D12-C

Product

Non-Isolated / POL

Output Power

12 W

Input Voltage Range

10 V to 14 V

Number Of Outputs

1

Output Voltage (channel 1)

0.75 V

Output Current (channel 1)

16 A

Output Type

Low Voltage

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Tape & Reel Surface Mount Package

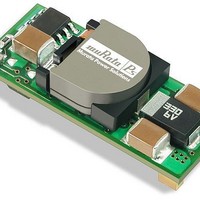

Murata Power Solutions’ LSM series DC/DC converters are the only higher-

current (16A) SMT DC/DCs that can be automatically “pick-and-placed” using

standard vacuum-pickup equipment (nozzle size and style, vacuum pressure

and placement speed may need to be optimized for automated pick and place)

and subsequently refl owed using high-temperature, lead-free solder.

assembled by their vendors with high-temperature solder (usually Sn96.5/

Ag3.5 with a melting point of +221°C) so that you may attach them to your

board using low-temperature solder (usually Sn63/Pb37 with a melting point

of +183°C). Conceptually straightforward, this “stepped” solder approach has

its limitations, and it is clearly out of step with an industry trending toward

the broad use of lead-free solders. Are you to experiment and develop refl ow

profi les from other vendors that ensure the components on those DC/DC never

exceed 215–216°C? If those components get too hot, “double-refl ow” could

compromise the reliability of their solder joints. Virtually all these devices

demand you “cool down” the Sn63 profi le you are likely using today.

Virtually all SMT DC/DCs today are unprotected “open-frame” devices

250

221

200

183

150

100

50

0

50

Sn96.5/Ag3.5 Melting Point

Sn63/Pb37 Melting Point

100

www.murata-ps.com

PCB TEMPERATURE INSIDE THE HEAT SHIELD

150

Figure 6. Refl ow Solder Profi le

Time (Seconds)

200

solders no one else has. Nevertheless, we have a simple and practical, straight-

forward approach that works. We assemble our LSM SMT DC/DCs using a

high-temperature (+216°C), lead-free alloy (Sn96.2%, Ag2.5%, Cu0.8%,

Sb0.5%). The LSM design ensures co-planarity to within 0.004 inches (100μm)

of the unit’s copper leads. These leads are gold-plated with a nickel underplate.

See Mechanical Data for additional information.

ing the package leads, provides thermal insulation to internal components

during refl ow and its smooth surface ideally doubles as the vacuum pick-up

location also. The insulation properties of the heat shield are so effective that

temperature differentials as high as 50°C develop inside-to-outside the shield.

Oven temperature profi les with peaks of 250–260°C and dwell times exceed-

ing 2 minutes above 221°C (the melting point of Sn96.5/Ag3.5) are easily

achieved.

MPS is not exempted from the Laws of Physics, and we do not have magic

The disposable heat shield (patent pending), which has a cutaway expos-

250

Non-Isolated, 13-80W SMT DC/DC Converters

HEAT SHIELD OUTSIDE TEMPERATURE

Technical enquiries email: sales@murata-ps.com, tel:

LSM-16A D12 Models

300

MDC_LSM 16A D12 Models.A05 Page 11 of 12

350

400

+1 508 339 3000