YC158TJR-07100KL Yageo, YC158TJR-07100KL Datasheet - Page 6

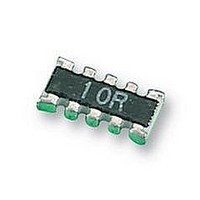

YC158TJR-07100KL

Manufacturer Part Number

YC158TJR-07100KL

Description

RESISTOR NETWORK, RNA310 1206 100K

Manufacturer

Yageo

Series

RNA310r

Datasheet

1.YC158TJR-07100KL.pdf

(8 pages)

Specifications of YC158TJR-07100KL

Resistance

100kohm

Resistance Tolerance

± 5%

Power Rating

310mW

Voltage Rating

25V

Temperature Coefficient

± 200ppm/°C

No. Of Elements

8

Resistor Case Style

1206

Svhc

No SVHC

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

YC158TJR-07100KL

Manufacturer:

Yageo

Quantity:

4 000

Company:

Part Number:

YC158TJR-07100KL

Manufacturer:

YAGEO

Quantity:

44 000

TESTS AND REQUIREMENTS

Short time

overload

Board Flex/

Bending

TEST

Life/

Operational Life/

Endurance

High

Temperature

Exposure/

Endurance at

upper category

temperature

Moisture

Resistance

Thermal Shock

Nov 14, 2008 V.3

Table 4 Test condition, procedure and requirements

Chip Resistor Surface Mount

TEST METHOD

MIL-STD-202G-method 108A

IEC 60115-1 4.25.1

JIS C 5202-7.10

MIL-STD-202G-method 108A

IEC 60115-1 4.25.3

JIS C 5202-7.11

MIL-STD-202G-method 106F

IEC 60115-1 4.24.2

MIL-STD-202G-method 107G

MIL-R-55342D-para 4.7.5

IEC60115-1 4.13

IEC60115-1 4.33

1,000 hours at 70±5 °C applied RCWV

1.5 hours on, 0.5 hour off, still air required

1,000 hours at maximum operating temperature

depending on specification, unpowered

No direct impingement of forced air to the parts

Tolerances: 155±3 °C

Each temperature / humidity cycle is defined at 8

hours (method 106F), 3 cycles / 24 hours for 10d

with 25 °C / 65 °C 95% R.H, without steps 7a &

7b, unpowered

Parts mounted on test-boards, without

condensation on parts

Measurement at 24±2 hours after

test conclusion

-55/+155 °C

Note: Number of cycles required is 300. Devices

unmounted

Maximum transfer time is 20 seconds. Dwell time

is 15 minutes. Air – Air

2.5 times RCWV or maximum overload voltage

whichever is less for 5 sec at room temperature

Device mounted on PCB test board as described,

only 1 board bending required

3 mm bending

Bending time: 60±5 seconds

Ohmic value checked during bending

PROCEDURE

YC

SERIES

158/358 (RoHS Compliant)

REQUIREMENTS

±(2%+0.05 Ω)

±(1%+0.05 Ω)

±(2%+0.05 Ω)

±(0.5%+0.05 Ω) for 10 KΩ to

10 MΩ

±(1%+0.05 Ω) for others

±(2%+0.05 Ω)

No visible damage

±(1%+0.05 Ω)

No visible damage

Product specification

www.yageo.com

6

8