66570-3 TE Connectivity, 66570-3 Datasheet - Page 4

66570-3

Manufacturer Part Number

66570-3

Description

D SUB CONTACT, PIN, 18AWG, SOLDER

Manufacturer

TE Connectivity

Type

Contactr

Series

AMPLIMITE HDP-20r

Specifications of 66570-3

Number Of Contacts

1POS

Number Of Terminals

1

Plug / Receptacle

PIN

Contact Plating

Au over Pd Ni

Contact Pitch (mm)

Not Requiredmm

Body Orientation

Straight

Mounting Style

Cable

Number Of Ports

1Port

Number Of Contact Rows

Not Required

Operating Temp Range

-55C to 105C

Termination Method

Solder Cup

Current Rating

3.7A

Housing Material

Not Required

Contact Material

Brass

Operating Voltage (max)

250VAC

Product Length (mm)

14.86mm

Product Depth (mm)

2.15mm

Wire Size (awg)

18

Contact Termination

Solder

Contact Type

Signal

Accessory Type

Pin & Socket Contact

Gender

Pin

Rohs Compliant

Yes

Contact Gender

Pin

Product Type

Contact

Product Series

HDP-20 (Crimp Snap)

Termination Method To Wire/cable

Solder

Insulation Support

No

Grade

Standard

Contact Retention In Housing

Crimp Snap-In

Solder Tail Contact Plating

Gold Flash over Nickel

Pin Diameter (mm [in])

1.02 [0.040]

Wire Range (mm² [awg])

0.8 - 0.9 [18]

Used With

CPC Connectors, AMPLIMITE HDP-20

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Gold Flash over Palladium Nickel or Gold (30) over Nickel

Contact Size

20

Contact Configuration

Solder Cup

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

4

4

Practical Values

The current-rating method

gives designers practical val-

ues applicable to their applica-

tions. While the specified

current levels for a contact may

be lower than for other testing

methods, they are more realis-

tic and simplify the system

design process.

“Spec-manship” is replaced by

a realistic assessment of the

current-carrying capacity of a

contact under varying condi-

tions of temperature, connector

loading, and wire size.

Connector/Contact

Acceptability

As previously stated, choosing

the correct connector/contact

combination is fundamental to

the successful function of all

connectors. The Selection

Chart shown below, is

designed to simplify your

choice of connectors and their

acceptable contacts. Once you

have selected the wire size,

current-carrying capacity need,

number of positions required,

and the type of contacts need-

ed in your choice of connector,

refer to this matrix for a quick

look at exactly what is accept-

able in a given connector type.

Contact Selection Chart

Next are rating factors, a table

of multipliers to account for

connector loading and for

smaller wire sizes. The

designer first determines the

base current for the ambient

conditions of the application;

then multiplies this base cur-

rent by the rating factors to

find the current level for the

application’s loading factor

and wire size.

(.125 POWERBAND)

CPCSeries 1

CPC Series 2

CPC Series 3

CPC Series 4

CPCSeries 5

CPCSeries 6

Connector

“G” Series

Metrimate

Metrimate

Metrimate

M Series

M Series

Drawer

Drawer

Special

Type

& Size 20

Upgrade

20 DF

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

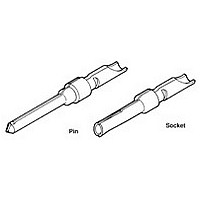

Precision Pin and Socket Contacts

Precision Pin and Socket Contacts

Current Carrying Capabilities

Technical Documents

Technical Documents consist

of Product Specifications and

Application Specifications.

Product Specifications define

the performance characteristics

of the product; i.e., Current

Rating, Temperature Rating,

etc. They are intended for the

Design or Component

Engineer. Application

Specifications describe how

the product is to be applied;

i.e., Crimping, Assembling,

etc. They are intended for

Manufacturing and Operation/

Set Up Personnel. Where Appli-

cation Specifications are not

available, an Instruction Sheet

is provided. Additional

Instruction Sheets on the prod-

uct may be available. Please

contact Technical Support:

1-800-522-6752.

Type I

An Example:

To demonstrate the method of

specifying current, consider the

following application conditions;

an ambient temperature of

65°C, a 50% loading of con-

tacts in the housing, and

20 AWG [0.6mm

From Figure 1, the base cur-

rent rating is 14 ampere with

18 AWG [0.8mm

Figure 2, the rating factor for

50% loading and 20 AWG

[0.6mm

The specific rating for this

application is the product of

the base rating and the rating

factor:

Each of the contacts can

carry 9.5 ampere.

However, if the ambient tem-

perature is 80°C the allow-

able T-rise becomes 25°C.

The base current must be

lowered to 12.8 ampere so

that the 105°C maximum

operating temperature is not

exceeded. The current rating

then becomes:

12.8 x 0.68 = 8.7 ampere.

14 x 0.68 = 9.5 ampere

2

] wire is 0.68.

Type II

2

] wire.

2

Dimensions are shown for

reference purposes only.

Specifications subject to change.

] wire.

Type III + &

Type II/III +

Upgrade

Rating factors allow the base current to be adjusted for various connec-

tor loading and wire sizes.

Type III +

Technical Document Selection Chart

Posted

.125 POWERBAND

M Series Posted

Size 8 Upgrade

(Continued)

Mini Coax

Type III+

Sub-Mini

Contact

Type XII

Type VI

Type II

Type I

Size 8

20 DF

Type

Coax

& Type XII

Upgrade

Type XII

Technical Support

USA: 1-800-522-6752

Canada: 1-905-475-6222

Mexico: 01-800-733-8926

Specifications

POWERBAND

108-40005

108-10108

108-10039

108-10042

108-10038

108-10037

108-10042

108-01317

108-14497

108-12021

108-12008

108-12011

Product

.125

—

Figure 2

Upgrade

&Size 8

Central America: 52-55-5-729-0425

South America: 55-11-3611-1514

www.tycoelectronics.com

Specifications

Size 8

Application

114-10000

114-40030

114-10037

114-10026

114-10004

114-10007

114-10005

114-10043

114-10014

—

—

—

—

Mini-Coax

Catalog 65910

Instruction

408-2024-3

408-09155

Revised 1-03

408-1770

Sheet

Sub-Mini

—

—

—

—

—

—

—

—

—

Coax