87667-2 TE Connectivity, 87667-2 Datasheet - Page 48

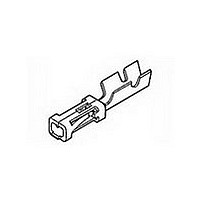

87667-2

Manufacturer Part Number

87667-2

Description

CONTACT, RECEPTACLE, 26-22AWG, CRIMP

Manufacturer

TE Connectivity

Type

Contactr

Series

Ampmodu Mod IVr

Specifications of 87667-2

Pitch (mm)

Not Requiredmm

Gender

RCP

Number Of Contacts

1POS

Number Of Contact Rows

Not Required

Mounting Style

Cable

Body Orientation

Straight

Contact Plating

Gold Over Nickel

Operating Temp Range

-65C to 105C

Termination Method

Crimp

Current Rating (max)

3A

Voltage Rating Max

250VAC

Contact Material

Beryllium Copper

Contact Resistance Max

12mOhm

Housing Material

Not Required

Housing Color

Not Required

Product Length (mm)

11.53mm

Connector Type

Contact, Crimp

Current Rating

3A

Contact Termination

Crimp

Rohs Compliant

Yes

Contact Type

Mod IV

Current, Ratings

3 A

Insulation Resistance

5000 Megohms

Material, Contact

Beryllium Copper

Plating, Contact Mating Area

Gold (30)

Plating, Contact Termination Area

Gold Flash over Nickel

Standards

UL Listed, CSA Certified, RoHS Compliant, ELV Compliant

Temperature, Operating, Maximum

105 °C

Temperature, Operating, Minimum

-65 °C

Thickness, Insulation

0.061 in.

Voltage, Dielectric Strength

750 V

Voltage, Rating

250

Wire Range

26 to 22 AWG

Wire Termination Type

Crimp

Contact Gender

Socket

Product Type

Contact

Termination Method To Wire/cable

Crimp

Wire Insulation Diameter (mm [in])

1.55 [0.061]

Connector Series

Mod IV

With Insulation Support

Yes

Applied Pressure

Standard

Contact - Rated Current (a)

3

Voltage Rating (vac)

250

Termination Resistance (m?)

12

Insulation Resistance (m?)

5,000

Dielectric Withstanding Voltage (v)

750

Crimp Area Plating

Gold Flash

Wire Range (mm [awg])

0.12-0.40² [26-22]

Contact Plating, Mating Area, Material

Gold (30)

Contact Base Material

Beryllium Copper

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Approved Standards

UL E28476, CSA LR7189

Operating Temperature (°c)

-65 – +105

Applies To

Wire/Cable

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

For Use With

Mod IV Series Connectors

Lead Free Status / Rohs Status

RoHS Compliant part

5

270

Catalog 1307819

Catalog 1307819

Revised 6-04

Revised 6-04

www.tycoelectronics.com

www.tycoelectronics.com

Material and Finish:

Housing—High temperature

thermoplastic, Color - Black, 94V-0

rated

Posts—Brass, plated as follows:

Plating A—Duplex plated .000030

[.00076] gold on contact area,

.000100 [.00254] min. tin-lead on

solder area, with entire post

underplated .000050 [.00127]

nickel.

Plating B—Duplex plated .000015

[.00038] gold on contact area,

.000100 [.00254] min. tin-lead on

solder area, with entire post

underplated .000050 [.00127]

nickel.

Plating C—.000100 [.00254] tin

lead over .000050 [.00127] nickel

on entire contact/post

Recommended

PC Board Layout

(Refer to MTE Application Spec.

114-25026 for Stencil Aperature

Layout using .006 [0.152] or .008

[0.203] stencil thickness

Related Product Data:

Mateable AMPMODU MTE

Products:

Receptacle Assemblies

(Polarized/Latching)—

pages 247, 248

Receptacle Assemblies with

Guide Ribs (installed in Single-

Row Coupling Shroud)—

pages 249, 250, 252, 257

Other Mateable Connectors:

Flexible Film Connectors—

Catalog 82007

Technical Documents

(

Product Specification

108-25034

Application Specification

114-25026

pages 295, 296):

Dimensions are in inches and

Dimensions are in inches and

millimeters unless otherwise

millimeters unless otherwise

specified. Values in brackets

specified. Values in brackets

are metric equivalents.

are metric equivalents.

AMPMODU Interconnection System

MTE Headers, Vertical, Polarized/Latching, Surface Mount

No. of

[0.62]

.025 Typ.

P o s .

[0.64]

1 0 1 . 1 0 0[ 2 7 . 9 4 ]

1 1 1 . 2 0 0[ 3 0 . 4 8 ]

1 2 1 . 3 0 0[ 3 3 . 0 2 ]

1 3 1 . 4 0 0[ 3 5 . 5 6 ]

1 4 1 . 5 0 0[ 3 8 . 1 0 ]

1 5 1 . 6 0 0[ 4 0 . 6 4 ]

1 6 1 . 7 0 0[ 4 3 . 1 8 ]

1 7 1 . 8 0 0[ 4 5 . 7 2 ]

1 8 1 . 9 0 0[ 4 8 . 2 6 ]

1 9 2 . 0 0 0[ 5 0 . 8 0 ]

2 0 2 . 1 0 0[ 5 3 . 3 4 ]

2 1 2 . 2 0 0[ 5 5 . 8 8 ]

2 2 2 . 3 0 0[ 5 8 . 4 2 ]

2 3 2 . 4 0 0[ 6 0 . 9 6 ]

2 4 2 . 5 0 0[ 6 3 . 5 0 ]

2 5 2 . 6 0 0[ 6 6 . 0 4 ]

.025

2

3

4

5

6

7

8

9 1 . 0 0 0[ 2 5 . 4 0 ]

[5.08]

.200

. 3 0 0[ 7 . 6 2 ]

. 4 0 0[ 1 0 . 1 6 ]

. 5 0 0[ 1 2 . 7 0 ]

. 6 0 0[ 1 5 . 2 4 ]

. 7 0 0[ 1 7 . 7 8 ]

. 8 0 0[ 2 0 . 3 2 ]

. 9 0 0[ 2 2 . 8 6 ]

Typ.

[2.54]

.100

[7.62]

A

.313

Plated Thru-Hole

Ø

.052 ±

[1.32 ±

Ø

[1.78±0.05]

.070±.002

.002

.003

0.05

0.07

1 . 0 2 0[ 2 5 . 9 1 ]

1 . 1 2 0[ 2 8 . 4 5 ] 1 . 0 0 0[ 2 5 . 4 0 ]

1 . 2 2 0[ 3 0 . 9 9 ] 1 . 1 0 0[ 2 7 . 9 4 ]

1 . 3 2 0[ 3 3 . 5 3 ] 1 . 2 0 0[ 3 0 . 4 8 ]

1 . 4 2 0[ 3 6 . 0 7 ] 1 . 3 0 0[ 3 3 . 0 2 ]

1 . 5 2 0[ 3 8 . 6 1 ] 1 . 4 0 0[ 3 5 . 5 6 ]

1 . 6 2 0[ 4 1 . 1 5 ] 1 . 5 0 0[ 3 8 . 1 0 ]

1 . 7 2 0[ 4 3 . 6 9 ] 1 . 6 0 0[ 4 0 . 6 4 ]

1 . 8 2 0[ 4 6 . 2 3 ] 1 . 7 0 0[ 4 3 . 1 8 ]

1 . 9 2 0[ 4 8 . 7 7 ] 1 . 8 0 0[ 4 5 . 7 2 ]

2 . 0 2 0[ 5 1 . 3 1 ] 1 . 9 0 0[ 4 8 . 2 6 ]

2 . 1 2 0[ 5 3 . 8 5 ] 2 . 0 0 0[ 5 0 . 8 0 ]

2 . 2 2 0[ 5 6 . 3 9 ] 2 . 1 0 0[ 5 3 . 3 4 ]

2 . 3 2 0[ 5 8 . 9 3 ] 2 . 2 0 0[ 5 5 . 8 8 ]

2 . 4 2 0[ 6 1 . 4 7 ] 2 . 3 0 0[ 5 8 . 4 2 ]

2 . 5 2 0[ 6 4 . 0 1 ] 2 . 4 0 0[ 6 0 . 9 6 ]

. 2 2 0[ 5 . 5 9 ]

. 3 2 0[ 8 . 1 3 ]

. 4 2 0[ 1 0 . 6 7 ]

. 5 2 0[ 1 3 . 2 1 ]

. 6 2 0[ 1 5 . 7 5 ]

. 7 2 0[ 1 8 . 2 9 ]

. 8 2 0[ 2 0 . 8 3 ]

. 9 2 0[ 2 3 . 3 7 ]

Dimensions are shown for

Dimensions are shown for

reference purposes only.

reference purposes only.

Specifications subject

Specifications subject

to change.

to change.

]

B

A

B

[1.40±0.08]

Position No. 1 Indicator

.055±.003

D i m e n s i o n s

E

. 1 0 0[ 2 . 5 4 ]

. 2 0 0[ 5 . 0 8 ]

. 3 0 0[ 7 . 6 2 ]

. 4 0 0[ 1 0 . 1 6 ]

. 5 0 0[ 1 2 . 7 0 ]

. 6 0 0[ 1 5 . 2 4 ]

. 7 0 0[ 1 7 . 7 8 ]

. 8 0 0[ 2 0 . 3 2 ]

. 9 0 0[ 2 2 . 8 6 ]

K

K

[2.54]

C

.100

C

D

Typ.

[1.90]

.075

[3.05]

.120

[13.59]

.535

1 . 0 2 0[ 2 5 . 9 2 ]

1 . 1 2 0[ 2 8 . 4 6 ]

1 . 2 2 0[ 3 1 . 0 0 ]

1 . 3 2 0[ 3 3 . 5 4 ]

1 . 4 2 0[ 3 6 . 0 8 ]

1 . 5 2 0[ 3 8 . 6 2 ]

1 . 6 2 0[ 4 1 . 1 6 ]

1 . 7 2 0[ 4 3 . 7 0 ]

1 . 8 2 0[ 4 6 . 2 4 ]

1 . 9 2 0[ 4 8 . 7 8 ]

2 . 0 2 0[ 5 1 . 3 2 ]

2 . 1 2 0[ 5 3 . 8 6 ]

2 . 2 2 0[ 5 6 . 4 0 ]

2 . 3 2 0[ 5 8 . 9 4 ]

2 . 4 2 0[ 6 1 . 4 8 ]

2 . 5 2 0[ 6 4 . 0 2 ]

. 2 2 0[ 5 . 6 0 ]

. 3 2 0[ 8 . 1 4 ]

. 4 2 0[ 1 0 . 6 8 ]

. 5 2 0[ 1 3 . 2 2 ]

. 6 2 0[ 1 5 . 7 6 ]

. 7 2 0[ 1 8 . 3 0 ]

. 8 2 0[ 2 0 . 8 4 ]

. 9 2 0[ 2 3 . 3 8 ]

USA: 1-800-522-6752

USA: 1-800-522-6752

Canada: 1-905-470-4425

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

C. America: 52-55-5-729-0425

[1.52]

.063

D

[1.53]

0.06

1 . 0 1 0[ 2 5 . 6 6 ]

1 . 0 6 0[ 2 6 . 9 3 ]

1 . 1 1 0[ 2 8 . 2 0 ]

1 . 1 6 0[ 2 9 . 4 7 ]

1 . 2 1 0[ 3 0 . 7 4 ]

1 . 2 6 0[ 3 2 . 0 1 ]

. 1 1 0[ 2 . 8 0 ]

. 1 6 0[ 4 . 0 7 ]

. 2 1 0[ 5 . 3 4 ]

. 2 6 0[ 6 . 6 1 ]

. 3 1 0[ 7 . 8 8 ]

. 3 6 0[ 9 . 1 5 ]

. 4 1 0[ 1 0 . 4 2 ]

. 4 6 0[ 1 1 . 6 9 ]

. 5 1 0[ 1 2 . 9 6 ]

. 5 6 0[ 1 4 . 2 3 ]

. 6 1 0[ 1 5 . 5 0 ]

. 6 6 0[ 1 6 . 7 7 ]

. 7 1 0[ 1 8 . 0 4 ]

. 7 6 0[ 1 9 . 3 1 ]

. 8 1 0[ 2 0 . 5 8 ]

. 8 6 0[ 2 1 . 8 5 ]

. 9 1 0[ 2 3 . 1 2 ]

. 9 6 0[ 2 4 . 3 9 ]

[2.88]

.113

[2.25±0.08]

.088±.003

E

Position No. 1

Pick and Place Cap

[5.76]

1 - 1 3 7 5 5 8 3 - 0

1 - 1 3 7 5 5 8 3 - 1

1 - 1 3 7 5 5 8 3 - 2

1 - 1 3 7 5 5 8 3 - 3

1 - 1 3 7 5 5 8 3 - 4

1 - 1 3 7 5 5 8 3 - 5

1 - 1 3 7 5 5 8 3 - 6

1 - 1 3 7 5 5 8 3 - 7

1 - 1 3 7 5 5 8 3 - 8

1 - 1 3 7 5 5 8 3 - 9

2 - 1 3 7 5 5 8 3 - 0

2 - 1 3 7 5 5 8 3 - 1

2 - 1 3 7 5 5 8 3 - 2

2 - 1 3 7 5 5 8 3 - 3

2 - 1 3 7 5 5 8 3 - 4

.227

1 3 7 5 5 8 3 - 1

1 3 7 5 5 8 3 - 2

1 3 7 5 5 8 3 - 3

1 3 7 5 5 8 3 - 4

1 3 7 5 5 8 3 - 5

1 3 7 5 5 8 3 - 6

1 3 7 5 5 8 3 - 7

1 3 7 5 5 8 3 - 8

1 3 7 5 5 8 3 - 9

Plating A

Section K-K

South America: 55-11-3611-1514

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

Japan: 81-44-844-8013

UK: 44-141-810-8967

UK: 44-141-810-8967

Vertical SMT Headers

1 - 1 3 7 5 5 8 2 - 0

1 - 1 3 7 5 5 8 2 - 1

1 - 1 3 7 5 5 8 2 - 2

1 - 1 3 7 5 5 8 2 - 3

1 - 1 3 7 5 5 8 2 - 4

1 - 1 3 7 5 5 8 2 - 5

1 - 1 3 7 5 5 8 2 - 6

1 - 1 3 7 5 5 8 2 - 7

1 - 1 3 7 5 5 8 2 - 8

1 - 1 3 7 5 5 8 2 - 9

2 - 1 3 7 5 5 8 2 - 0

2 - 1 3 7 5 5 8 2 - 1

2 - 1 3 7 5 5 8 2 - 2

2 - 1 3 7 5 5 8 2 - 3

2 - 1 3 7 5 5 8 2 - 4

1 3 7 5 5 8 2 - 1

1 3 7 5 5 8 2 - 2

1 3 7 5 5 8 2 - 3

1 3 7 5 5 8 2 - 4

1 3 7 5 5 8 2 - 5

1 3 7 5 5 8 2 - 6

1 3 7 5 5 8 2 - 7

1 3 7 5 5 8 2 - 8

1 3 7 5 5 8 2 - 9

Plating B

[5.84]

.230

1 - 1 3 7 5 5 4 9 - 0

1 - 1 3 7 5 5 4 9 - 1

1 - 1 3 7 5 5 4 9 - 2

1 - 1 3 7 5 5 4 9 - 3

1 - 1 3 7 5 5 4 9 - 4

1 - 1 3 7 5 5 4 9 - 5

1 - 1 3 7 5 5 4 9 - 6

1 - 1 3 7 5 5 4 9 - 7

1 - 1 3 7 5 5 4 9 - 8

1 - 1 3 7 5 5 4 9 - 9

2 - 1 3 7 5 5 4 9 - 0

2 - 1 3 7 5 5 4 9 - 1

2 - 1 3 7 5 5 4 9 - 2

2 - 1 3 7 5 5 4 9 - 3

2 - 1 3 7 5 5 4 9 - 4

1 3 7 5 5 4 9 - 1

1 3 7 5 5 4 9 - 2

1 3 7 5 5 4 9 - 3

1 3 7 5 5 4 9 - 4

1 3 7 5 5 4 9 - 5

1 3 7 5 5 4 9 - 6

1 3 7 5 5 4 9 - 7

1 3 7 5 5 4 9 - 8

1 3 7 5 5 4 9 - 9

Plating C