350699-1 TE Connectivity, 350699-1 Datasheet - Page 6

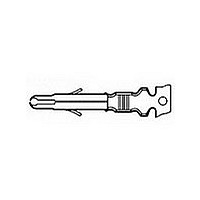

350699-1

Manufacturer Part Number

350699-1

Description

UMNL SPLIT PIN PTPBR

Manufacturer

TE Connectivity

Type

Contactr

Specifications of 350699-1

Gender

Pin

Body Orientation

Straight

Housing Material

Not Required

Number Of Contacts

1POS

Number Of Ports

1Port

Number Of Terminals

1

Current Rating (max)

19A

Pitch (mm)

Not Requiredmm

Contact Material

Brass

Operating Temp Range

-55C to 125C

Voltage Rating Max

600VAC

Mounting Style

Cable

Termination Method

Crimp

Contact Plating

Pre-Tin

Product Height (mm)

3.68mm

Product Depth (mm)

3.56mm

Product Length (mm)

20.07mm

Product Type

Contacts

Contact Gender

Pin (Male)

Voltage Rating

600 V

Current Rating

19 A

Termination Style

Quick Connect

Wire Gauge Range

24-18

Product Line

Universal MATE-N-LOK

Insulation Diameter (mm [in])

1.02-2.54 [.040-.100]

High Current

No

Current Rating (a)

19

Voltage (vac)

600

Solder Tail Contact Plating

Pre-Tin

Wire Range (mm [awg])

0.20-0.80² [24-18]

Contact Diameter (mm [in])

2.18 [0.086]

Pin Style

Split

Stock Thickness (mm [in])

0.30 [0.012]

Contact Type

Pin

Contact Termination Type

Crimp

Contact Base Material

Brass

Sealable

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

350699-1

Manufacturer:

TE

Quantity:

35 000

Company:

Part Number:

350699-1

Manufacturer:

MOLEX

Quantity:

35 000

4.

4.1.

4.2.

4.3.

4.4.

4.5

Rev L

QUALITY ASSURANCE PROVISIONS

Qualification Testing

A.

B.

Requalification Testing

If changes significantly affecting form, fit or function are made to the product or manufacturing process,

product assurance shall coordinate requalification testing, consisting of all or part of the original testing

sequence as determined by development/product, quality and reliability engineering.

Acceptance

Acceptance is based on verification that the product meets the requirements of Figure 1. Failures

attributed to equipment, test setup or operator deficiencies shall not disqualify the product. If product

failure occurs, corrective action shall be taken and specimens resubmitted for qualification. Testing to

confirm corrective action is required before resubmittal.

Quality Conformance Inspection

The applicable quality inspection plan shall specify the sampling acceptable quality level to be used.

Dimensional and functional requirements shall be in accordance with the applicable product drawing

and this specification.

Certification

This product has been recognized under the Component Recognition Program of Underwriter’s

Laboratories Inc., Electrical File Number E-28476 and certified by Canadian Standards Association

Certification Number LR-16455.

Sample Selection

Connector housings and contacts shall be prepared in accordance with applicable Instruction

Sheets and shall be selected at random from current production. Test group 1 shall consist of 1

housing of each size, 5 pins and 5 sockets all representative of the entire lot being tested. Test

groups 2 through 4 shall consist of 4 connector assemblies per group. The housings and wire

sizes shall be chosen randomly to cover the range of the product line. Test group 5 samples shall

consist of 15 pin and socket contacts per wire size. Test group 6 samples shall consist of 15 pin

and socket contacts crimped on 14 AWG wire and tested with appropriate random housings. Test

group 7 samples shall consist of 15 random housings. All contacts shall be crimped to appropriate

part number 103501 and 103502 tin plated test conductors in accordance with Application

Specification 114-1010.

Test Sequence

Qualification inspection shall be verified by testing samples as specified in Figure 2.

108-1031

6 of 8