AD7147ACPZ-REEL Analog Devices Inc, AD7147ACPZ-REEL Datasheet - Page 38

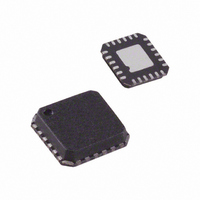

AD7147ACPZ-REEL

Manufacturer Part Number

AD7147ACPZ-REEL

Description

IC,Converter, Other/Special/Miscellaneous,LLCC,24PIN

Manufacturer

Analog Devices Inc

Series

CapTouch™r

Type

Capacitive Sensor Controllerr

Datasheet

1.AD7147ACPZ-1500RL7.pdf

(72 pages)

Specifications of AD7147ACPZ-REEL

Resolution (bits)

16 b

Data Interface

Serial, SPI™

Voltage Supply Source

Single Supply

Voltage - Supply

2.6 V ~ 3.6 V

Operating Temperature

-40°C ~ 85°C

Mounting Type

Surface Mount

Package / Case

24-LFCSP

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With

EVAL-AD7147EBZ - BOARD EVAL FOR AD7147ACPZEVAL-AD7147-1EBZ - BOARD EVAL FOR AD7147ACPZ-1

Sampling Rate (per Second)

-

Lead Free Status / Rohs Status

Compliant

AD7147

PCB DESIGN GUIDELINES

CAPACITIVE SENSOR BOARD MECHANICAL SPECIFICATIONS

Table 19.

Parameter

Distance from Edge of Any Sensor to Edge of Grounded Metal Object

Distance Between Sensor Edges

Distance Between Bottom of Sensor Board and Controller Board or Grounded

1

2

The distance is dependent on the application and the position of the switches relative to each other and with respect to the user’s finger position and handling.

Adjacent sensors with no space between them are implemented differentially.

The 1.0 mm specification is intended to prevent direct sensor board contact with any conductive material. This specification, however, does not guarantee an absence

of EMI coupling from the controller board to the sensors. To avoid potential EMI-coupling issues, place a grounded metal shield between the capacitive sensor board

and the main controller board, as shown in Figure 58.

Metal Casing

D

5

D

1

CONTROLLER PRINTED CIRCUIT BOARD OR METAL CASING

CAPACITIVE SENSOR

PRINTED CIRCUIT

Figure 57. Capacitive Sensor Board, Side View

Figure 56. Capacitive Sensor Board, Top View

SLIDER

2

CAPACITIVE SENSOR BOARD

METAL OBJECT

D

BUTTONS

2

1

SWITCH

8-WAY

D

D

4

3

Rev. B | Page 38 of 72

CHIP SCALE PACKAGES

The lands on the chip scale package (CP-24-3) are rectangular.

The PCB pad for these should be 0.1 mm longer than the package

land length and 0.05 mm wider than the package land width.

Center the land on the pad to maximize the solder joint size.

The bottom of the chip scale package has a central thermal pad.

The thermal pad on the printed circuit board should be at least

as large as this exposed pad. To avoid shorting, provide a clear-

ance of at least 0.25 mm between the thermal pad and the inner

edges of the land pattern on the PCB.

Thermal vias can be used on the PCB thermal pad to improve

the thermal performance of the package. If vias are used, they

should be incorporated in the thermal pad at a 1.2 mm pitch

grid. The via diameter should be between 0.3 mm and 0.33 mm,

and the via barrel should be plated with 1 oz copper to plug the via.

Connect the PCB thermal pad to GND.

D

5

Symbol

D

D

D

Figure 58. Capacitive Sensor Board with Grounded Shield

1

2

5

CONTROLLER PRINTED CIRCUIT BOARD OR METAL CASING

= D

3

= D

4

CAPACITIVE SENSOR BOARD

GROUNDED METAL SHIELD

Min

0.1

0

Typ

1.0

Max

Unit

mm

mm

mm