34080 TE Connectivity, 34080 Datasheet - Page 9

34080

Manufacturer Part Number

34080

Description

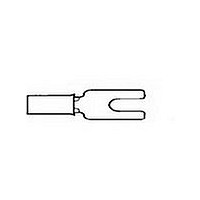

TERMINAL, SPADE/FORK, #6, CRIMP, RED

Manufacturer

TE Connectivity

Type

Spade Tongue Terr

Series

PIDGr

Specifications of 34080

Stud Size

3.5mm

Wire Gauge

16-22

Body Plating

Tin

Body Material

Copper

Insulation

Nylon

Product Depth (mm)

7.54mm

Product Length (mm)

19.13mm

Color

Red

Connector Type

Fork / Spade Tongue

Insulator Color

Red

Termination Method

Crimp

Stud/tab Size

#6

Wire Size (awg)

22-16

Contact Material

Copper

Contact Plating

Tin

Rohs Compliant

Yes

Angle

Straight

Brand/series

PIDG

Diameter, Insulation

0.125 "

Gender

Female

Insulation Type

Nylon

Length, Overall

0.297 "

Material, Contact

Copper

Primary Type

Fork

Size, Stud

6

Special Features

One Barrel

Width, Overall

0.297 "

Wire Size

22-16 AWG

Product

Spades

Stud / Tab Size

6 (M3.5)

Insulation Material

Nylon

Voltage Rating

300 VAC

Terminal Shape

Spade Tongue

Receptacle Style

Straight

Body Style

PIDG

Barrel Type

Closed Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.18 [.125] Max.

Stud Diameter (mm [in])

3.51 [0.138]

Shape

SPADE-020

Heavy Duty

No

Finish

Tin

Voltage (vac)

300

Wire/cable Size (cma)

509 – 3,260

Wire Range (mm [awg])

0.30-1.40² [22-16]

Tongue Material Thickness (mm [in])

0.84 [0.033]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

34080

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

34080

Manufacturer:

MOLEX

Quantity:

35 000

Company:

Part Number:

34080-1003

Manufacturer:

MOLEX

Quantity:

34 000

Company:

Part Number:

34080-1003

Manufacturer:

MOLEX

Quantity:

35 000

Company:

Part Number:

340801003

Manufacturer:

MOLEX

Quantity:

55 507

3.7. Bend Allowance

Upward and downward bend of the terminated terminal, splice, or end cap must be within the tolerance

provided in Figure 9.

3.8. Repair

Damaged or defective terminal, splice, or end cap must not be used. If damage is evident, the terminal, splice,

or end cap should be cut from the wire and replaced with a new one. Crimped terminals, splices, or end caps

MUST NOT be re–terminated or re–used by removing the wire.

Datum Line

Datum Line

Datum Line

Rev D

(Sketches represent the uppermost wire insulation range of the Terminals, Splice, or End Cap. Thinner wire insulation

Detail A

11

11

Cross-Section of Insulation Crimp At Wire End of Terminals, Splice, or End Cap

Too Loose

may appear slightly different, but will perform the same.) Refer to Figure 2.

T erminal, Splice, or

End Cap Insulation

PIDG Terminals, Splices, and End Caps

Detail B

Center of Crimp

Center of Splice

Center of Crimp

Figure 8

Figure 9

Terminal

End Cap

Splice

Correct

Wire

Insulation

Metal

Sleeve

Detail C

11

11

Too Tight

11

11

11

11

114-2157

9 of 14