40523 TE Connectivity, 40523 Datasheet - Page 49

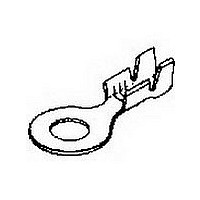

40523

Manufacturer Part Number

40523

Description

RING 12-10

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.40523.pdf

(76 pages)

Specifications of 40523

Stud Size

4.16mm

Wire Gauge

10-12

Body Plating

Tin

Body Material

Brass

Insulation

Non-Insulated

Product Depth (mm)

8.71mm

Product Length (mm)

17.2mm

Color

Not Required

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Open Barrel

Wire/cable Type

Regular Wire

Insulation Support

Non-Insulation Support

Stud Diameter (mm [in])

4.17 [0.164]

Shape

RING-015

Heavy Duty

No

Finish

Tin

Wire Range (mm [awg])

3.00-6.00² [12-10]

Stock Thickness (mm [in])

1.02 [0.040]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

AMPLIVAR Product

Terminator (APT)

Product Facts

I

I

I

I

I

Specifications

Weight — Approximately 150 lb

[68 kg] with CQM

Width — 38 [965] with CQM and

product reel

Depth — 35 [889]

Height — 14 [356]

Electrical — 120 VAC, 60 Hz, 1 A, 1f,

or 240 VAC, 50 Hz, .5 A, 1f

Air — 80-100 psi [5.52-7.59 bar],

22 scfm [0.000141 m3/s]

Catalog 82227

Revised 8-04

www.tycoelectronics.com

(679984-1) for direct connect

No need to strip magnet

wire

Connects up to 3 wires in

1 splice

Crimp Quality Monitor

(CQM) system measures

crimp heights

Machine shut height easily

adjusts in .0005 [0.013]

increments

Quick-change tooling with-

out major shut-height

adjustments

APT III A with vertical base

terminals

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Machine Applied Terminations, Open Barrel Terminals

(Rings, Spades, Pins, Receptacles, Splices, Tabs)

AMPLIVAR Application Tooling

For pigtail splice connection

of magnet wire, the

AMPLIVAR Product

Terminator (APT) and strip-

form AMPLIVAR products

offer a fast and efficient

system, with no need to

strip mag-wire insulation.

To apply a splice, simply

place the wires in the target

area and depress the foot

switch. The machine

automatically shears the

splice from the strip, crimps

it, shears off excess wire,

and advances the next

splice into position.

APT semi-automatic bench

machines are available in

two versions: the IIIA with

automatic precision

adjustment controlled by

the Crimp Quality Monitor

(CQM), and the IIE with

manual precision

adjustment.

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

With CQM, the APT IIIA

assists in achieving 6-sigma

processing capability. In

addition to providing 100%

inspection and automatic

adjustment of crimp heights

as needed, the CQM also

evaluates the quality of

each crimp. If a

questionable crimp is

detected, visual and

audible alarms alert the

operator.

For operations with multiple

wire sizes, the APT IIIA

provides programmable

sequencing of different

crimp-height settings, and

it can store up to 2,000

different programs of 7

different settings each.

The maximum time to

auto-adjust between

programmed crimp heights

is 2 seconds.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

APT III A

The lower cost, manual

adjust IIE is a simpler

version without CQM

capability, with the

advantage of faster

set-up times.

To avoid the need to

change product reels when

wire combinations are

smaller than the CMA range

of the splice, an optional

stuffer (part no. 679323-1 for

APT IIIA, part no. 679323-2

for APT IIE.) inserts a stuffer

wire into the splice prior

to crimping, increasing

the total CMA to the

recommended range.

The wire stuffer unit is for

pigtail splices only.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

APT II E

49