RE65GR500C02 Vishay, RE65GR500C02 Datasheet - Page 4

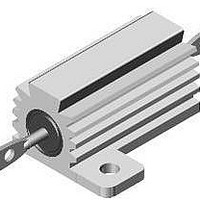

RE65GR500C02

Manufacturer Part Number

RE65GR500C02

Description

RH-10 .5 1% RE65GR500 C02

Manufacturer

Vishay

Type

Wirewoundr

Specifications of RE65GR500C02

Resistance

0.5 Ohms

Tolerance

1 %

Power Rating

10 Watts

Temperature Coefficient

+/- 100 PPM / C

Operating Temperature Range

- 55 C to + 250 C

Dimensions

10.67 mm Dia. x 20.32 mm W x 19.05 mm L x 9.91 mm H

Product

Power Resistors Wire Wound Aluminum Housed

Power Rating(s)

10W

Tolerance (+ Or -)

1%

Mounting Style

Flange

Construction

Chassis

Operating Temp Range

-55C to 250C

Case Style

Aluminum Housed

Termination Style

Axial

Military Standard

MIL-PRF-18546

Product Length (mm)

34.93mm

Product Height (mm)

9.91mm

Product Depth (mm)

20.32mm

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

MATERIAL SPECIFICATIONS

Element: Copper-nickel alloy or nickel-chrome alloy,

depending on resistance value

Core: Ceramic, steatite or alumina, depending on physical

size

Encapsulant: Silicone molded construction

Housing: Aluminum with hard anodic coating

End Caps: Stainless steel

Standard Terminals: For RH100 and RH250 terminals are

threaded stainless steel. All others are 60/40 tin/lead (Sn/Pb)

w/Nickel underplate on copper clad steel core terminal.

Part Marking: Dale, model, wattage, value, tolerance, date

code

Document Number: 30282

Revision: 23-Feb-11

PERFORMANCE

TEST

Thermal Shock

Short Time Overload

Dielectric Withstanding Voltage

Temperature

Moisture Resistance

Shock, Specified Pulse

Vibration, High Frequency

Load Life

Terminal Strength

Wirewound Resistors, Military, MIL-PRF-18546 Qualified,

5 x rated power for 5 s

MIL-STD-202 Method 106, 7b not applicable

Rated power applied until thermally stable,

then a minimum of 15 min at - 55 °C

1000 V

4500 V

250 °C for 2 h

MIL-STD-202 Method 213, 100 g’s for 6 ms, 10 shocks

Frequency varied 10 Hz to 2000 Hz, 20 g peak, 2 directions 6 h each

1000 h at rated power, + 25 °C, 1.5 h “ON”, 0.5 h “OFF”

30 s, 5 pound pull test for RE60 and RE65,

10 pound pull test for other sizes;

torque test - 24 pound inch for RE77 and 32 pound inch for RE80

Type RE, Aluminum Housed, Chassis Mount

For technical questions, contact:

rms

rms

for RE60, RE65 and RE70; 2000 V

for RE77 and RE80; duration 1 min

CONDITIONS OF TEST

ww2bresistors@vishay.com

NON-INDUCTIVE (TYPE N)

Models of equivalent physical and electrical specifications

are available with non-inductive (Aryton-Perry) winding.

They are identified by substituting the letter N for G in the

model number (RE60N, for example).

rms

for RE75;

± (0.5 % + 0.05 ) R

± (0.5 % + 0.05 ) R

± (0.2 % + 0.05 ) R

± (0.5 % + 0.05 ) R

± (1.0 % + 0.05 ) R

± (0.2 % + 0.05 ) R

± (0.2 % + 0.05 ) R

± (1.0 % + 0.05 ) R

± (0.2 % + 0.05 ) R

RE Military

TEST LIMITS

Vishay Dale

www.vishay.com

4