171662-1 TE Connectivity, 171662-1 Datasheet - Page 71

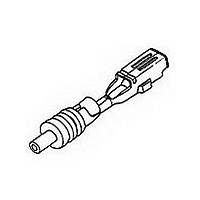

171662-1

Manufacturer Part Number

171662-1

Description

E-J MK-2 070 REC CONT

Manufacturer

TE Connectivity

Type

Contactr

Series

070r

Datasheet

1.171662-1.pdf

(80 pages)

Specifications of 171662-1

Gender

RCP

Body Orientation

Straight

Housing Material

Not Required

Number Of Contacts

1POS

Number Of Ports

1Port

Number Of Terminals

1

Pitch (mm)

Not Requiredmm

Contact Material

Brass

Operating Temp Range

-30C to 105C

Mounting Style

Cable

Termination Method

Crimp

Contact Plating

Pre-Tin

Product Height (mm)

3.6mm

Product Depth (mm)

5.4mm

Product Length (mm)

16.5mm

Product Line

Econoseal J

Product Type

Contact

Wire/cable Type

Discrete Wire

Cable Type

Thin Wall

Termination Method To Wire/cable

Crimp

Wire/cable Size (awg)

16 – 20

Wire/cable Size (mm²)

0.5 – 1.25

Wire Type

Stranded

Contact Type

Socket

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Pre-Tin

Contact Plating, Mating Area, Thickness (µm [?in])

0.76 [29.92]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

2.00 – 2.60 [0.079 – 0.102]

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Reel

Packaging Quantity

6000

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

171662-1

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

171662-1

Manufacturer:

TE/TYCO

Quantity:

6 600

A

AMP Sealed Connectors

AMP Technical Support Center/AMP FAX Service

1-800-522-6752 717-986-7777

Stripper-Crimper

Applicators (coded SCA)

Side-Feed Heavy-Duty

Miniature Applicators

(coded HDM)

AMP Sealed Connectors

Application Tooling

AMP-O-MATIC Stripper-

Crimper Machines,

854040-3, -4

(Continued)

Interchangeable applicators

for crimping products reeled

side-by-side on single or

dual carrier strips (primarily

closed-barrel terminals and

open-barrel contacts).

Similar design as the end-

feed version. All side-feed

applicators include a wire

stop to help correctly

position the wire end in the

crimping target area.

Interchangeable applicators

for crimping products in

AMP-O-MATIC Stripper-

Crimper Machines. Consist

of separate ram and lower

tooling assemblies. Similar

dial-in settings for different

wire sizes and insulation

diameters as HDM

applicators. Available with

sensors for use with the

Crimp Quality Monitor.

Semiautomatic bench

crimping machines that also

strip the wire, and are

therefore used for

terminating jacketed cable.

Feature manual precision

adjustment of crimp height,

keyed strip blades for

faster, more accurate

setups, and an efficient

scrap removal system. All

adjustments can be made

from the front of the

machines without special

tools. Available with crimp

quality monitoring.

Dimensions are in

millimeters over [inches]

www.amp.com

For more information, request

Instruction Sheet 408-8040.

For more information, request

Catalog 65004 (AMP-O-MATIC

Stripper-Crimper Machines),

Catalog 82275 [Crimp Quality

Monitor (CQM)].

Specifications

Width—14 [355]

Depth—18 [457]

Height—33 [838] without reel

Weight—150 lb [68 kg]

Electrical—120 VAC, 50 or

60 Hz, .5 A

Air—80-100 psi [5.52-6.90 bar],

3.5 scfm [0.00165 m

Wire Range—32-14 AWG

[0.03-2 mm

For more information, request

Catalog 65004, Video 198075,

Catalog 82275 [Crimp Quality

Monitor (CQM)], Video 198094.

2

]

Specifications

subject to change.

Revised 01-00

3

/s]

Catalog

65481

71