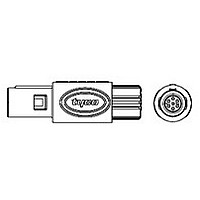

2-1877847-0 TE Connectivity, 2-1877847-0 Datasheet

2-1877847-0

Specifications of 2-1877847-0

Related parts for 2-1877847-0

2-1877847-0 Summary of contents

Page 1

... Product shall be of the design, construction and physical dim ensions specified on the applicable product drawing. 3.2. Materials Materials used in the construction of this product shall be as specified on the applicable product drawing. ©2011 Tyco Electronics Corporation, | Indicates change a TE Connectivity Ltd. Company *Trademark All Rights Reserved TE logo is a trademark. ...

Page 2

... Perform ance and Test Description Product is designed to m eet the electrical, m echanical and environm ental perform ance requirem ents specified in Figure 2. Unless otherwise specified, all tests shall be perform bient environm ental conditions per EIA-364. 3.5. Test Requirem ents and Procedures Sum m ary Test Description Initial exam ination of product ...

Page 3

... Three shocks in each direction applied along 3 m utually perpendicular planes, 18 total shocks. EIA-364-9. Mate and unm ate specim ens for 2500 cycles axim um rate of 500 cycles per hour. EIA-364-13. Measure force necessary to m ate specim ens axim um rate of 12 [0.5 in] per m inute. ...

Page 4

... Numbers indicate sequence in which tests are performed. (d) Precondition specimens with 10 durability cycles. Rev B Requirem ent See Note. Figure 2 (end) Test Group ( Test Sequence ( 3,7 2,4 2 3(d) 3( Figure 3 108-2249 Procedure EIA-364-65, Class IIA (4 gas). Subject m ated specim ens to environm ental Class IIA for 20 days 2,6 3 ...

Page 5

... Acceptance Acceptance is based on verification that the product m eets the requirem ents of Figure 2. Failures attributed to equipm ent, test setup or operator deficiencies shall not disqualify the product. If product failure occurs, corrective action shall be taken and specim ens resubm itted for qualification. Testing to confirm corrective action is required before resubm ittal ...