5-643821-1 TE Connectivity, 5-643821-1 Datasheet - Page 3

5-643821-1

Manufacturer Part Number

5-643821-1

Description

21P MTA156 CONN ASSY 26AWG LF

Manufacturer

TE Connectivity

Specifications of 5-643821-1

Connector Type

Connector Assembly

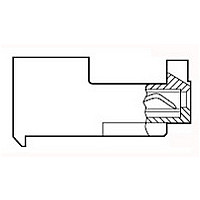

Connector Design

Closed End

Product Line

MTA-156

Termination Method To Wire/cable

IDC Standard

Wire Size (mm² [awg])

0.12-0.15² [26]

Mating Connector Lock

With

Four Points Of Contact

Without

Shrouded

No

Mounting Ears

Without

Mating Connector Lock Type

Locking Ramp

Panel Mount Retention

Without

Current Rating (a)

7

Voltage Rating (vac)

600

Solder Tail Contact Plating

Bright Tin

Number Of Positions

21

Centerline (mm [in])

3.96 [0.156]

Narrow

No

Post Number(s) Omitted

None

Cable Exit Angle

90°

Contact Type

Socket

Contact Plating, Mating Area, Material

Tin

Contact Base Material

Copper Alloy

Connector Style

Receptacle

Housing Color

Blue

Mating Alignment

With

Ul Flammability Rating

UL 94V-2

Housing Material

Nylon

Mating Alignment Type

Polarizing Tab

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Application Use

Wire-to-Board

Termination tensile strength,

perpendicular, unmated.

Vibration, sinusoidal.

Vibration, random.

Mechanical shock.

Durability.

Mating force.

Unmating force.

Thermal shock.

Rev J

Test Description

No discontinuities of 1 microsecond

or longer duration.

See Note.

No discontinuities of 1 microsecond

or longer duration.

See Note.

No discontinuities of 1 microsecond

or longer duration.

See Note.

See Note.

Standard contact: 1.75 pounds

maximum per contact.

High force contact: 6 pounds

maximum per contact.

Gold contact: 1.25 pounds

maximum per contact.

Standard contact: .2 pound

minimum per contact.

High force contact: .7 pound

minimum per contact.

Gold contact: .1 pound minimum

per contact.

See Note.

Wire Size

AWG

26

24

22

20

18

Figure 1 (continued)

ENVIRONMENTAL

Requirement

Pounds Minimum

Slot Tensile

1.3

1.3

3.4

4.0

4.6

TE Spec 109-16.

Determine slot tensile strength by

pulling perpendicular to terminated

wire at maximum rate of 1 inch per

minute.

See Figure 5.

TE Spec 109-21-1.

Subject mated samples to 10-55-10

Hz traversed in 1 minute with 0.06

inch maximum total excursion. Two

hours in each of 3 mutually

perpendicular planes.

See Figure 6.

TE Spec 109-21-7.

Subject mated samples to 3.15 G's

rms between 5-500 Hz. Fifteen

minutes in each of 3 mutually

perpendicular planes.

See Figure 6.

TE Spec 109-26-1.

Subject mated samples to 50 G's

half-sine shock pulses of 11

milliseconds duration. Three shocks

in each direction applied along 3

mutually perpendicular planes, 18

total shocks.

See Figure 6.

TE Spec 109-27.

With header mounted in fixture,

manually mate and unmate

samples for 25 cycles.

TE Spec 109-42, Condition A.

Measure force necessary to mate

samples with header at maximum

rate of .5 inch per minute. Calculate

force per contact.

TE Spec 109-42, Condition A.

Measure force necessary to unmate

samples from header at maximum

rate of .5 inch per minute. Calculate

force per contact.

TE Spec 109-22.

Subject mated samples to 25 cycles

between -55 and 105° C.

Procedure

108-1051

3 of 10