2-111623-3 TE Connectivity, 2-111623-3 Datasheet

2-111623-3

Specifications of 2-111623-3

Related parts for 2-111623-3

2-111623-3 Summary of contents

Page 1

... All inspections shall be performed using the applicable inspection plan and product drawing. 1.3. Qualification Test Results Successful qualification testing on the subject product line was completed on 24Jun94. The Qualification Test Report number for this testing is 501-254. This documentation is on file at and available from Engineering Practices and Standards (EPS). 2. APPLICABLE DOCUMENTS The following TE Connectivity (TE) documents form a part of this specification to the extent specified herein ...

Page 2

... Procedure Visual, dimensional and functional per applicable quality inspection plan. TE Spec 109-6-6. Subject mated contacts assembled in housing to 20 millivolt open circuit at 100 milliamperes. See Figure 4. TE Spec 109-29-1. 300 volts AC (rms). Test between adjacent contacts of unmated connector assemblies. TE Spec 109-28-3. ...

Page 3

... Mixed flowing gas. Temperature life. Shall meet visual requirements, show no physical damage, and shall meet the requirements of NOTE additional tests as specified in the Product Qualification Test Sequence in Figure 2. Rev C Requirement 1. ozf] maximum per contact. TE Spec 109-42, Condition A. 0.14N [0.5 ozf] minimum per contact ...

Page 4

... Humidity/temperature cycling Mixed flowing gas Temperature life (a) See paragraph 4.1.A. NOTE (b) Numbers indicate sequence in which tests are performed. (c) Precondition samples with 5 durability cycles. Rev C Test Group ( Test Sequence (b) 1,9 1,5 1,5 1,8 3,7 2,4 2,4 3,7 2 3(c) 3(c) Figure 2 108-1372 5 1,5 2 ...

Page 5

... Connector size (reference) Recommended cable length (cm) B. Test Sequence Qualification inspection shall be verified by testing samples as specified in Figure 2. 4.2. Requalification Testing If changes significantly affecting form, fit or function are made to the product or manufacturing process, product assurance shall coordinate requalification testing, consisting of all or part of the original testing sequence as determined by development/product, quality and reliability engineering ...

Page 6

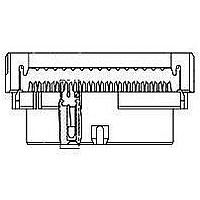

... Termination Resistance & Temperature Measurement Points Mounting & Clamping Location For Vibration & Physical Shock Rev C Figure 4 Top View Side View Figure 5 108-1372 ...