M39014/01-1553 Kemet, M39014/01-1553 Datasheet - Page 5

M39014/01-1553

Manufacturer Part Number

M39014/01-1553

Description

CAP CER .1UF 50V 10% RADIAL

Manufacturer

Kemet

Series

Military, MIL-PRF-39014, CKR05r

Specifications of M39014/01-1553

Capacitance

0.1µF

Voltage - Rated

50V

Tolerance

±10%

Temperature Coefficient

X7R

Mounting Type

Through Hole

Operating Temperature

-55°C ~ 125°C

Applications

General Purpose

Ratings

-

Package / Case

Radial

Size / Dimension

0.190" L x 0.090" W (4.83mm x 2.29mm)

Height - Seated (max)

0.200" (5.08mm)

Thickness (max)

-

Lead Spacing

0.200" (5.08mm)

Features

Military

Lead Style

Flat Bent

Lead Free Status / Rohs Status

Contains lead / RoHS non-compliant

Other names

C052T104K5X5CR

CKR05BX104KR

M39014/01-1553

CKR05BX104KR

M39014/01-1553

8

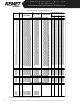

two representative KEMET series: C052 and C062. Power dis-

sipation capability for various mounting configurations is shown

in Table 3. This table was extracted from Engineering Bulletin

F-2013, which provides a more detailed treatment of this sub-

ject.

the two sizes in spite of a 2 to 1 surface area ratio. Due to the

materials used in the construction of multilayer ceramic capac-

itors, the power dissipation capability does not depend greatly

on the surface area of the capacitor body, but rather on how

well heat is conducted out of the capacitor lead wires.

Consequently, this power dissipation capability is applicable to

other leaded multilayer styles and sizes.

the capacitor is very sensitive to the details of its use environ-

ment. The temperature rise due to power dissipation should not

exceed 20°C. Using that constraint, the maximum permissible

power dissipation may be calculated from the data provided in

Table 3.

bility into a permissible AC voltage rating. Assuming a sinu-

soidal wave form, the RMS “ripple voltage” may be calculated

The data necessary to make this calculation is included in

Engineering Bulletin F-2013. However, the following criteria

must be observed:

from the following formula:

1.00" leadwires attached to binding post

of GR-1615 bridge (excellent heat sink)

0.25" leadwires attached to binding post

of GR-1615 bridge

Capacitor mounted flush to 0.062" glass-

epoxy circuit board with small copper traces

Capacitor mounted flush to 0.062" glass-

epoxy circuit board with four square inches

of copper land area as a heat sink

Power dissipation has been empirically determined for

Note that no significant difference was detected between

As shown in Table 3, the power dissipation capability of

It is often convenient to translate power dissipation capa-

Provided that these criteria are met, multilayer ceramic

1. The temperature rise due to power dissipation

2. The peak AC voltage plus the DC voltage must not

Mounting Configuration

© KEMET Electronics Corporation, P.O. Box 5928, Greenville, S.C. 29606, (864) 963-6300

should be limited to 20°C.

exceed the maximum working voltage of the

capacitor.

POWER DISSIPATION CAPABILITY

(Rise in Celsius degrees per Watt)

Where

E = Z x

POWER DISSIPATION

E = RMS Ripple Voltage (volts)

P = Power Dissipation (watts)

Z = Impedance

R = ESR

TABLE 3

P

R

MAX

90 Celsius degrees

rise per Watt ±10%

55 Celsius degrees

rise per Watt ±10%

77 Celsius degrees

rise per Watt ±10%

53 Celsius degrees

rise per Watt ±10%

of C052 & C062

Dissipation

APPLICATION NOTES FOR MULTILAYER

Power

CERAMIC CAPACITORS

capacitors may be operated with AC voltage applied without

need for DC bias.

extremely reliable and, for all practical purposes, has an infi-

nite life span when used within the maximum voltage and

temperature ratings. Capacitor failure may be induced by sus-

tained operation at voltages that exceed the rated DC voltage,

voltage spikes or transients that exceed the dielectric with-

standing voltage, sustained operation at temperatures above

the maximum rated temperature, or the excessive tempera-

ture rise due to power dissipation.

1,000 hours or in FITS (failure per billion hours). Some

KEMET series are qualified under U.S. military established

reliability specifications MIL-PRF-20, MIL-PRF-123, MIL-

PRF-39014, and MIL-PRF-55681. Failure rates as low as

0.001% per 1,000 hours are available for all capacitance /

voltage ratings covered by these specifications. These spec-

ifications and accompanying Qualified Products List should

be consulted for details.

an internal testing program is maintained by KEMET Quality

Assurance. Samples from each week’s production are sub-

jected to a 2,000 hour accelerated life test at 2 x rated voltage

and maximum rated temperature. Based on the results of

these tests, the average failure rate for all non-military series

covered by this test program is currently 0.06% per 1,000

hours at maximum rated conditions. The failure rate would be

much lower at typical use conditions. For example, using MIL-

HDBK-217D this failure rate translates to 0.9 FITS at 50%

rated voltage and 50°C.

er ceramic capacitor series are available on request.

if they are misapplied. Typical misapplications include expo-

sure to excessive voltage, current or temperature. If the

dielectric layer of the capacitor is damaged by misapplication

the electrical energy of the circuit can be released as heat,

which may damage the circuit board and other components

as well.

that precautions be taken to protect personnel and equipment

during initial application of voltage. Commonly used precau-

tions include shielding of personnel and sensing for excessive

power drain during board testing.

working environments. While the chips themselves are quite

robust in other environments, solderability will be degraded

by exposure to high temperatures, high humidity, corrosive

atmospheres, and long term storage. In addition, packaging

materials will be degraded by high temperature – reels may

soften or warp, and tape peel force may increase. KEMET

recommends that maximum storage temperature not exceed

40˚ C, and maximum storage humidity not exceed 70% rela-

tive humidity. In addition, temperature fluctuations should be

minimized to avoid condensation on the parts, and atmos-

pheres should be free of chlorine and sulfur bearing com-

pounds. For optimized solderability, chip stock should be

used promptly, preferably within 1.5 years of receipt.

A well constructed multilayer ceramic capacitor is

Failure rate is usually expressed in terms of percent per

For series not covered by these military specifications,

Current failure rate details for specific KEMET multilay-

Ceramic capacitors, like any other capacitors, may fail

If potential for misapplication exists, it is recommended

Ceramic chip capacitors should be stored in normal

STORAGE AND HANDLING

MISAPPLICATION

RELIABILITY