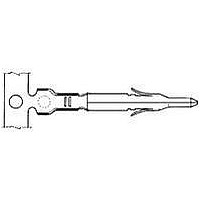

770835-1 TE Connectivity, 770835-1 Datasheet

770835-1

Specifications of 770835-1

Available stocks

Related parts for 770835-1

770835-1 Summary of contents

Page 1

... Materials Materials used in the construction of this product shall be as specified on the applicable product drawing. ©2011 Tyco Electronics Corporation, | Indicates change a TE Connectivity Ltd. Company *Trademark All Rights Reserved TE logo is a trademark. For latest revision, visit our website at www.te.com/documents. For Regional Customer Service, visit our website at www.te.com Other products, logos, and company names might be trademarks of their respective owners ...

Page 2

Ratings ! Voltage: 600 volts Current: 11.2 amperes maximum ! Temperature: -55 to 105° C 3.4. Performance and Test Description Product is designed to meet the electrical, mechanical and environmental performance requirements specified in Figure ...

Page 3

Test Description Vibration, sinusoidal. Mechanical shock. Durability. Contact retention. Contact insertion force. Mating force. Unmating force. Housing lock strength. Housing panel retention. Thermal shock. Rev D Requirement No discontinuities of 10 microseconds or longer duration. See Note. No discontinuities of ...

Page 4

Test Description Humidity/temperature cycling. Temperature life. Mixed flowing gas. Shall meet visual requirements, show no physical damage, and meet requirements of additional NOTE tests as specified in the Product Qualification and Requalification Test Sequence shown in Figure 2. Rev D ...

Page 5

Product Qualification and Requalification Test Sequence A. Test Reports CTL1314-004 and CTL7166-007 Test or Examination Initial examination of product Dry circuit resistance Insulation resistance Withstanding voltage Temperature rise vs current Termination tensile strength Vibration, sinusoidal Mechanical shock Durability Contact ...

Page 6

B. Test Report EA20100461T Initial examination of product Dry circuit resistance Temperature rise vs current Vibration, sinusoidal Mechanical shock Durability Mating force Unmating force Termination tensile strength Temperature life Mixed flowing gas Final examination of product (a) See paragraph 4.1.A. ...

Page 7

QUALITY ASSURANCE PROVISIONS 4.1. Qualification Testing A. Specimen Selection Specimens shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. All test groups shall each consist of 5 random connector assemblies. ...

Page 8

Test Reports CTL1314-004 and CTL7166-007 Wire Size (AWG determine acceptable current carrying capacity for percentage connector NOTE loading and wire gage indicated, use the Multiplication ...

Page 9

Wire Size (AWG determine acceptable current carrying capacity for percentage connector NOTE loading and wire gage indicated, use the Multiplication Factor (F) from the above chart and multiply it times the Base rated Current for a single circuit ...

Page 10

Rev D Figure 5 Vibration Mounting Fixture Figure 6 Mechanical Shock Mounting Fixture 108-1542 ...