7-848076-5 TE Connectivity, 7-848076-5 Datasheet

7-848076-5

Specifications of 7-848076-5

Related parts for 7-848076-5

7-848076-5 Summary of contents

Page 1

... In the event of conflict between the requirem ents of this specification and the referenced docum ents, this specification shall take precedence. 2.1. Tyco Electronics Docum ents ! 109 Series: Test Specifications as indicated in Figure 1 ! 109-197: Test Specification (AMP Test Specifications vs EIA and IEC Test Methods) ! 114- : Application Specification ! 501- : Qualification Test Report 2 ...

Page 2

Materials Materials used in the construction of this product shall be as specified on the applicable product drawing. 3.3. Ratings ! Voltage: • 1/2I: 10 kilovolts • 1/2LI: 15 kilovolts • 1I: 20 kilovolts • 1LI: 25 kilovolts • ...

Page 3

... See Figure 4. EIA-364-32. Subject specim ens to 5 cycles between -55 and 125 C. EIA-364-31, Method II, Condition A. Subject specim ens and 90 to 95% RH for 96 hours. EIA-364-17, Method A, Test Condition 5, Test Tim e Condition A. Subject m ated specim ens to 125 C for 96 hours ...

Page 4

... NOTE (b) Numbers indicate sequence in which tests are performed. (c) This test group is applicable to hermetic seal type receptacles only. (d) HiPot is performed at each temperature extreme and reduced barometric pressure, 70000 feet. Rev O2 Requirem ent See Note. -8 Leakage rate less than He/sec. See Note. ...

Page 5

QUALITY ASSURANCE PROVISIONS 4.1. Qualification Testing A. Specim en Selection Specim ens shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. Test group 1 shall consist of 28 lead assem ...

Page 6

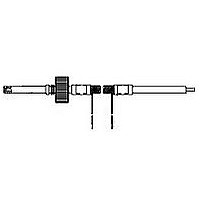

Gage Num ber 1 2 (a) Contact: Size 16 NOTE (b) Material: Tungsten carbide Rev O2 Figure 3 Contact Resistance Measurem ent Points A Dim ension .0165 +.0001/-.0000 .0635 +.0000/-.0001 Figure 4 Engaging & Separating Gage 108-36033 B Dim ension ...