NZ10150-T1 Seoul Semiconductor Inc, NZ10150-T1 Datasheet - Page 15

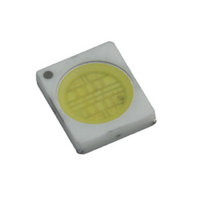

NZ10150-T1

Manufacturer Part Number

NZ10150-T1

Description

LED WARM WHITE 3000K DIFF SMD

Manufacturer

Seoul Semiconductor Inc

Series

Z Power Z1r

Specifications of NZ10150-T1

Color

White, Warm

Current - Test

400mA

Luminous Flux @ Current - Test

75lm

Current - Max

450mA

Lumens @ Current - Max

83lm

Lumens/watt @ Current - Test

45lm/W

Voltage - Forward (vf) Typ

4.2V

Wavelength

3000K

Lens Style/size

Round, 4.6mm

Viewing Angle

120°

Mounting Type

Surface Mount

Package / Case

6.00mm L x 5.00mm W x 1.20mm H

For Use With

876-1003 - LM3406 LED DRIVER EVAL BOARD

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

897-1015-2

(1) During processing, mechanical stress on the surface should be minimized as much as

possible. Sharp objects of all types should not be used to pierce the sealing compound.

(2) In general, LEDs should only be handled from the side. By the way, this also applies

to LEDs without a silicone sealant, since the surface can also become scratched.

(3) When populating boards in SMT production, there are basically no restrictions

regarding the form of the pick and place nozzle, except that mechanical pressure on the

surface of the resin must be prevented.

This is assured by choosing a pick and place nozzle which is larger than the LED’s

reflector area.

(4) Silicone differs from materials conventionally used for the manufacturing of LEDs.

These conditions must be considered during the handling of such devices. Compared to

standard encapsulants, silicone is generally softer, and the surface is more likely to

attract dust.

As mentioned previously, the increased sensitivity to dust requires special care

during processing. In cases where a minimal level of dirt and dust particles cannot be

guaranteed, a suitable cleaning solution must be applied to the surface after the

soldering of components.

(5) SSC suggests using isopropyl alcohol for cleaning. In case other solvents are used, it

must be assured that these solvents do not dissolve the package or resin.

Ultrasonic cleaning is not recommended. Ultrasonic cleaning may cause damage to the

LED.

Handling of Silicone Resin LEDs

Document No. : SSC-QP-7-07-24 (Rev.00)

www.acriche.com

www.acriche.com

October. 2010

October. 2010

Rev. 10

Rev. 10