UQQ-5/17-Q12PB-C Murata Power Solutions Inc, UQQ-5/17-Q12PB-C Datasheet - Page 17

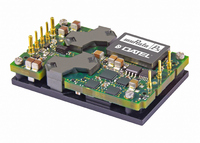

UQQ-5/17-Q12PB-C

Manufacturer Part Number

UQQ-5/17-Q12PB-C

Description

CONV DC/DC 85W 17A 5V T/H

Manufacturer

Murata Power Solutions Inc

Series

UQQr

Type

Isolatedr

Datasheet

1.UQQ-128-Q12PB-C.pdf

(18 pages)

Specifications of UQQ-5/17-Q12PB-C

Output

5V

Number Of Outputs

1

Power (watts)

85W

Mounting Type

Through Hole

Voltage - Input

9 ~ 36V

Package / Case

8-DIP Module, 1/4 Brick

1st Output

5 VDC @ 17A

Size / Dimension

2.22" L x 1.45" W x 0.50" H (56.4mm x 36.8mm x 12.7mm)

Power (watts) - Rated

85W

Operating Temperature

-40°C ~ 85°C

Efficiency

90.5%

Approvals

CSA, cUL, EN, UL

Dc / Dc Converter O/p Type

Fixed

No. Of Outputs

1

Input Voltage

9V To 36V

Power Rating

85W

Output Voltage

5V

Output Current

17A

Approval Bodies

EN, IEC, UL

Supply Voltage

12V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3rd Output

-

2nd Output

-

4th Output

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

811-1892-5

Calculating Maximum Power Dissipation

To determine the maximum amount of internal power dissipation, fi nd the

ambient temperature inside the enclosure and the airfl ow (in Linear Feet per

Minute – LFM) at the converter. Determine the expected heat dissipation using

the Effi ciency curves and the converter Input Voltage. You should also compen-

sate for lower atmospheric pressure if your application altitude is considerably

above sea level.

The general proceedure is to compute the expected temperature rise of the

heatsink. If the heatsink exceeds +100°C. either increase the airfl ow and/or

reduce the power output. Start with this equation:

where “Ta” is the enclosure ambient air temperature and,

where “Ts” is the heatsink temperature and,

where “R4 [at airfl ow]” is a specifi c heat transfer thermal resistance (in

degrees Celsius per Watt) for a particular heat sink at a set airfl ow rate. We

have already estimated R4 [at airfl ow] in the equations above.

Note particularly that Ta is the air temperature inside the enclosure at the

heatsink, not the outside air temperature. Most enclosures have higher

internal temperatures, especially if the converter is “downwind” from other

heat-producing circuits. Note also that this “Pd” term is only the internal heat

dissipated inside the converter and not the total power output of the converter.

We can rearrange this equation to give an estimated temperature rise of the

heatsink as follows:

Heat Sink Example

Assume an effi ciency of 92% and power output of 100 Watts. Using equation

[4], Pd is about 8.7 Watts at an input voltage of 48 Volts. Using +30°C ambient

temperature inside the enclosure, we wish to limit the heat sink temperature to

+90°C maximum baseplate temperature to stay well away from thermal shut-

down. The +90°C. fi gure also allows some margin in case the ambient climbs

above +30°C or the input voltage varies, giving us less than 92% effi ciency.

The heat sink and airfl ow combination must have the following characteristics:

Since the ambient thermal resistance of the heatsink and pad is 12.5°C/W, we

need additional forced cooling to get us down to 6.9°C/W. Using a hypothetical

airfl ow constant of 0.005, we can rearrange equation [5] as follows:

Heatsink Kit *

Model Number

HS-QB25-UVQ

HS-QB50-UVQ

HS-QB100-UVQ

* Kit includes heatsink, thermal pad and mounting hardware. These are

non-RoHS models. For RoHS-6 versions, add “-C” to the model number

(e.g., HS-QB25-UVQ-C).

(Required Airfl ow, LFM) x (Airfl ow Constant) = R4[Nat.Convection] /

R4[at airfl ow] –1, or,

(Required Airfl ow, LFM) x (Airfl ow Constant) = 12.5/6.9 –1 = 0.81

Internal Heat Dissipation [Pd in Watts] = (Ts – Ta)/R4 [at airfl ow] [6]

Ts = (Pd x R4 [at airfl ow]) + Ta [7]

8.7 W = (90-30) / R4[airfl ow] or,

R4[airfl ow] = 60/8.7 = 6.9°C/W

These model numbers are correct for the UQQ series.

Still Air (Natural convection)

thermal resistance

10.6°C/Watt

12°C/Watt

8°C/Watt

Heatsink height

0.25" (6.35mm)

0.50" (12.7mm)

1.00" (25.4mm)

(see drawing)

www.murata-ps.com

On/Off Enable Control Ground Bounce Protection

To improve reliability, if you use a small signal transistor or other external

circuit to select the Remote On/Off control, make sure to return the LO side

directly to the –Vin power input on the DC/DC converter. To avoid ground

bounce errors, do not connect the On/Off return to a distant ground plane or

current-carrying bus. If necessary, run a separate small return wire directly to

the –Vin terminal. There is very little current (typically 1-5 mA) on the On/Off

control however, large current changes on a return ground plane or ground bus

can accidentally trigger the converter on or off. If possible, mount the On/Off

transistor or other control circuit adjacent to the converter.

and, rearranging again,

162 LFM is the minumum airfl ow to keep the heatsink below +90°C. Increase

the airfl ow to several hundred LFM to reduce the heatsink temperature further

and improve life and reliability.

Do not connect

control transistor

through remote

power bus

(Required Airfl ow, LFM) = 0.81/0.005 = 162 LFM

(2.54)

Wide Input Range Single Output DC/DC Converters

0.10

On/Off

Control

Transistor

* UQQ SERIES HEATSINKS ARE AVAILABLE IN 3 HEIGHTS:

Figure 9. On/Off Enable Control Ground Bounce Protection

0.140 DIA. (3.56) (4 PLACES)

MATERIAL: BLACK ANODIZED ALUMINUM

0.25 (6.35), 0.50 (12.70) AND 1.00 (25.4)

Ground plane or power return bus

Dimensions in inches (mm)

Figure 8. Optional Heatsink

(57.91)

(47.24)

1.860

2.28

Preferred location

of On/Off control

adjacent to -Vin

terminal

25 Mar 2011 MDC_UQQ.B01 Page 17 of 18

email: sales@murata-ps.com

UQQ Series

Install separate

return wire for

On/Off control

with remote

transistor

(26.16)

1.03

*

DC/DC Converter

(36.83)

1.45

+ Vin

On/Off Enable

-Vin return