LM3405XEVAL National Semiconductor, LM3405XEVAL Datasheet - Page 11

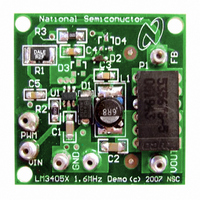

LM3405XEVAL

Manufacturer Part Number

LM3405XEVAL

Description

BOARD EVALUATION LM3405X

Manufacturer

National Semiconductor

Series

PowerWise®r

Specifications of LM3405XEVAL

Current - Output / Channel

1A

Outputs And Type

1, Non-Isolated

Voltage - Output

0.2 ~ 13.5 V

Features

Dimmable

Voltage - Input

3 ~ 15V

Utilized Ic / Part

LM3405

Kit Contents

Board, Datasheet

Svhc

No SVHC (15-Dec-2010)

Kit Features

Cycle-by-Cycle Current Limit,

Rohs Compliant

No

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

capacitor will have high ESL and a 0805 ceramic chip capac-

itor will have very low ESL. At the operating frequency of the

LM3405, certain capacitors may have an ESL so large that

the resulting inductive impedance (2πfL) will be higher than

that required to provide stable operation. It is strongly recom-

mended to use ceramic capacitors due to their low ESR and

low ESL. A 10µF multilayer ceramic capacitor (MLCC) is a

good choice for most applications. In cases where large ca-

pacitance is required, use surface mount capacitors such as

Tantalum capacitors and place at least a 1µF ceramic capac-

itor close to the V

X7R or X5R dielectrics. Consult capacitor manufacturer

datasheet to see how rated capacitance varies over operating

conditions.

OUTPUT CAPACITOR (C2)

The output capacitor is selected based upon the desired re-

duction in LED current ripple. A 1µF ceramic capacitor results

in very low LED current ripple for most applications. Due to

the high switching frequency, the 1µF capacitor alone (without

feed-forward capacitor C4) can filter more than 90% of the

inductor current ripple for most applications where the sum of

LED dynamic resistance and R1 is larger than 1Ω. Since the

internal compensation is tailored for small output capacitance

with very low ESR, it is strongly recommended to use a ce-

ramic capacitor with capacitance less than 3.3µF.

Given the availability and quality of MLCCs and the expected

output voltage of designs using the LM3405, there is really no

need to review other capacitor technologies. A benefit of ce-

ramic capacitors is their ability to bypass high frequency

noise. A certain amount of switching edge noise will couple

through the parasitic capacitances in the inductor to the out-

put. A ceramic capacitor will bypass this noise. In cases where

large capacitance is required, use Electrolytic or Tantalum

capacitors with large ESR, and verify the loop performance

on bench. Like the input capacitor, recommended multilayer

ceramic capacitors are X7R or X5R. Again, verify actual ca-

pacitance at the desired operating voltage and temperature.

Check the RMS current rating of the capacitor. The maximum

RMS current rating of the capacitor is:

One may select a 1206 size ceramic capacitor for C2, since

its current rating is typically higher than 1A, more than enough

for the requirement.

FEED-FORWARD CAPACITOR (C4)

The feed-forward capacitor (designated as C4) connected in

parallel with the LED string is required to provide multiple

benefits to the LED driver design. It greatly improves the large

signal transient response and suppresses LED current over-

shoot that may otherwise occur during PWM dimming; it also

helps to shape the rise and fall times of the LED current pulse

during PWM dimming thus reducing EMI emission; it reduces

LED current ripple by bypassing some of inductor ripple from

flowing through the LED. For most applications, a 1µF ce-

ramic capacitor is sufficient. In fact, the combination of a 1µF

feed-forward ceramic capacitor and a 1µF output ceramic ca-

pacitor leads to less than 1% current ripple flowing through

the LED. Lower and higher C4 values can be used, but bench

validation is required to ensure the performance meets the

application requirement.

Figure 13 shows a typical LED current waveform during PWM

dimming without feed-forward capacitor. At the beginning of

IN

pin. For MLCCs it is recommended to use

11

each PWM cycle, overshoot can be seen in the LED current.

Adding a 1µF feed-forward capacitor can totally remove the

overshoot as shown in Figure 14.

CATCH DIODE (D1)

The catch diode (D1) conducts during the switch off-time. A

Schottky diode is required for its fast switching time and low

forward voltage drop. The catch diode should be chosen such

that its current rating is greater than:

The reverse breakdown rating of the diode must be at least

the maximum input voltage plus appropriate margin. To im-

prove efficiency, choose a Schottky diode with a low forward

voltage drop.

BOOST DIODE (D2)

A standard diode such as the 1N4148 type is recommended.

For V

small-signal Schottky diode is recommended for better effi-

ciency. A good choice is the BAT54 small signal diode.

FIGURE 14. PWM Dimming with a 1µF Feed-Forward

FIGURE 13. PWM Dimming without Feed-Forward

BOOST

circuits derived from voltages less than 3.3V, a

I

D1

Capacitor

Capacitor

= I

F

x (1-D)

20178969

20178970

www.national.com