B82498F3121J EPCOS Inc, B82498F3121J Datasheet - Page 9

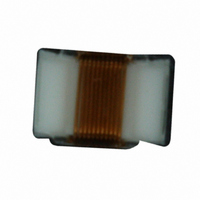

B82498F3121J

Manufacturer Part Number

B82498F3121J

Description

INDUCTOR 120NH 440MA 0805 5%

Manufacturer

EPCOS Inc

Series

SIMIDr

Type

Ceramicr

Datasheet

1.B82498F3829K.pdf

(10 pages)

Specifications of B82498F3121J

Inductance

120nH

Tolerance

±5%

Package / Case

0805 (2012 Metric)

Current

440mA

Dc Resistance (dcr)

310 mOhm Max

Q @ Freq

50 @ 250MHz

Self Resonant Freq

1.25GHz

Mounting Type

Surface Mount

Frequency - Test

150MHz

Material - Core

Ceramic

Applications

General Purpose

Dimensions

1.7 mm W x 2.3 mm L x 1.4 mm H

Product

Inductors

Test Frequency

250 MHz

Maximum Dc Current

440 mA

Maximum Dc Resistance

0.31 Ohms

Self Resonant Frequency

1.25 GHz

Q Minimum

50

Operating Temperature Range

- 55 C to + 150 C

Termination Style

SMD/SMT

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Shielding

-

Current - Saturation

-

Current - Temperature Rise

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

495-3433-2

B82498F3121J000

B82498F3121J000

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

B82498F3121J000

Manufacturer:

TDK/东电化

Quantity:

20 000

■

■

■

■

■

Please read Cautions and warnings and

Important notes at the end of this document.

Cautions and warnings

Please note the recommendations in our Inductors data book (latest edition) and in the data

sheets.

– Particular attention should be paid to the derating curves given there.

– The soldering conditions should also be observed. Temperatures quoted in relation to wave

If the components are to be washed varnished it is necessary to check whether the washing

varnish agent that is used has a negative effect on the wire insulation, any plastics that are used,

or on glued joints. In particular, it is possible for washing varnish agent residues to have a

negative effect in the long-term on wire insulation.

The following points must be observed if the components are potted in customer applications:

– Many potting materials shrink as they harden. They therefore exert a pressure on the plastic

– It is necessary to check whether the potting material used attacks or destroys the wire

– The effect of the potting material can change the high-frequency behaviour of the components.

Ferrites are sensitive to direct impact. This can cause the core material to flake, or lead to

breakage of the core.

Even for customer-specific products, conclusive validation of the component in the circuit can

only be carried out by the customer.

soldering refer to the pin, not the housing.

housing or core. This pressure can have a deleterious effect on electrical properties, and in

extreme cases can damage the core or plastic housing mechanically.

insulation, plastics or glue.

9

03/08