AD8555ACP-R2 Analog Devices Inc, AD8555ACP-R2 Datasheet - Page 21

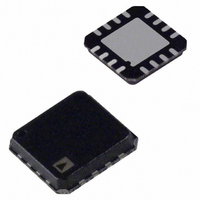

AD8555ACP-R2

Manufacturer Part Number

AD8555ACP-R2

Description

IC AMP CHOPPER 2MHZ 10MA 16LFCSP

Manufacturer

Analog Devices Inc

Series

DigiTrim®r

Datasheet

1.AD8555ARZ.pdf

(28 pages)

Specifications of AD8555ACP-R2

Rohs Status

RoHS non-compliant

Amplifier Type

Chopper (Zero-Drift)

Number Of Circuits

1

Slew Rate

1.2 V/µs

Gain Bandwidth Product

2MHz

Current - Input Bias

16nA

Voltage - Input Offset

2µV

Current - Supply

2mA

Current - Output / Channel

10mA

Voltage - Supply, Single/dual (±)

2.7 V ~ 5.5 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Surface Mount

Package / Case

16-LFCSP

Output Type

-

-3db Bandwidth

-

Initial State

Initially, all the polysilicon fuses are intact. Each parameter has

the value 0 assigned (see Table 12).

Table 12. Initial State before Programming

Second Stage Gain Code = 0

First Stage Gain Code = 0

Output Offset Code = 0

Master Fuse = 0

When power is applied to a device, parameter values are taken

either from internal registers if the master fuse is not blown or

from the polysilicon fuses if the master fuse is blown.

Programmed values have no effect until the master fuse is

blown. The internal registers feature power-on reset so that

unprogrammed devices enter a known state after power-up;

power-on reset occurs when VDD is between 0.7 V and 2.2 V.

Simulation Mode

The simulation mode allows any parameter to be changed tem-

porarily. These changes are retained until the simulated value is

reprogrammed, the power is removed, or the master fuse is

blown. Parameters are simulated by setting Field 1 to 01, select-

ing the desired parameter in Field 2, and the desired value for

the parameter in Field 4. Note that a value of 11 for Field 2 is

ignored during the simulation mode. Examples of temporary

settings follow:

• By setting the second stage gain code (Parameter 00) to 011

• By setting the first stage gain code (Parameter 01) to 000 1011

• Set the output offset code (Parameter 10) to 0100 0000 and

Programming Mode

Intact fuses give a bit value of 0. Bits with a desired value of 1

need to have the associated fuse blown. Since a relatively large

current is needed to blow a fuse, only one fuse can be reliably

blown at a time. Thus, a given parameter value may need sever-

al 38-bit words to allow reliable programming. A 5.5 V supply is

required when blowing fuses to minimize the on resistance of

the internal MOS switches that blow the fuse. The power supply

must be able to deliver 250 mA of current, and at least 0.1 μF of

decoupling capacitance is needed across the power pins of the

device. A minimum period of 1 ms should be allowed for each

and the second stage gain to 50, 1000 0000 0001 01 00 10

0000 0011 0111 1111 1110 is the result.

and the first stage gain to 4.166, 1000 0000 0001 01 01 10

0000 1011 0111 1111 1110 is the result.

A first stage gain of 4.166 with a second stage gain of 50 gives

a total gain of 208.3. This gain has a maximum tolerance of

2.5%.

the output offset to 1.260 V when VDD = 5 V and VSS = 0 V.

This output offset has a maximum tolerance of 0.8%: 1000

0000 0001 01 10 10 0100 0000 0111 1111 1110.

Second Stage Gain = 17.5

First Stage Gain = 4.0

Output Offset = VSS

Master Fuse Not Blown

Rev. A | Page 21 of 28

fuse to blow. There is no need to measure the supply current

during programming; the best way to verify correct program-

ming is to use the read mode to read back the programmed

values and to remeasure the gain and offset to verify these

values. Programmed fuses have no effect on the gain and output

offset until the master fuse is blown; after blowing the master

fuse, the gain and output offset are determined solely by the

blown fuses and the simulation mode is permanently deacti-

vated.

Parameters are programmed by setting Field 1 to 10, selecting

the desired parameter in Field 2, and selecting a single bit with

the value 1 in Field 4.

As an example, suppose the user wants to permanently set the

second stage gain to 50. Parameter 00 needs to have the value

0000 0011 assigned. Two bits have the value 1, so two fuses need

to be blown. Since only one fuse can be blown at a time, the

code 1000 0000 0001 10 00 10 0000 0010 0111 1111 1110 can be

used to blow one fuse. The MOS switch that blows the fuse

closes when the complete packet is recognized and opens when

the start-of-packet, dummy, or end-of-packet fields are no long-

er valid. After 1 ms, the second code 1000 0000 0001 10 00 10

0000 0001 0111 1111 1110 can be entered to blow the second

fuse.

To set the first stage gain permanently to a nominal value of

4.151, Parameter 01 needs to have the value 000 1011 assigned.

Three fuses need to be blown, and the following codes can be

used, with a 1 ms delay after each code:

1000 0000 0001 10 01 10 0000 1000 0111 1111 1110

1000 0000 0001 10 01 10 0000 0010 0111 1111 1110

1000 0000 0001 10 01 10 0000 0001 0111 1111 1110

To set the output offset permanently to a nominal value of

1.260 V when VDD = 5 V and VSS = 0 V, Parameter 10 needs to

have the value 0100 0000 assigned. One fuse needs to be blown,

and the following code can be used: 1000 0000 0001 10 10 10

0100 0000 0111 1111 1110.

Finally, to blow the master fuse to deactivate the simulation

mode and prevent further programming, the code 1000 0000

0001 10 11 10 0000 0001 0111 1111 1110 can be used.

There are a total of 20 programmable fuses. Since each fuse

requires 1 ms to blow, and each serial word can be loaded in

2.3 ms, the maximum time needed to program the fuses can be as

low as 66 ms.

Parity Error Detection

A parity check is used to determine whether the programmed

data of an AD8555 is valid, or whether data corruption has

occurred in the nonvolatile memory. Figure 52 shows the sche-

matic implemented in the AD8555.

AD8555